A compact water supply, designed to boost your system back into full compliance.

Pressurecheck is our highly engineered compact water supply solution designed to bring your sprinkler system back into full compliance.

Taking up roughly two car parking spaces, Pressurecheck is a very compact alternative to a pump and tank system. Pressurecheck works by drawing water from the town-mains supply to feed a sprinkler system which cannot reliably meet the minimum pressures required for a specific risk. It can also be used as a direct alternative to traditional pump and tanks systems, increasing valuable revenue space and streamlining installation.

As Pressurecheck is built and fully tested in our factory, it can be delivered and installed quickly with minimal disruption. Offering a unique plug-and-play design means that installation time and overall costs are dramatically reduced.

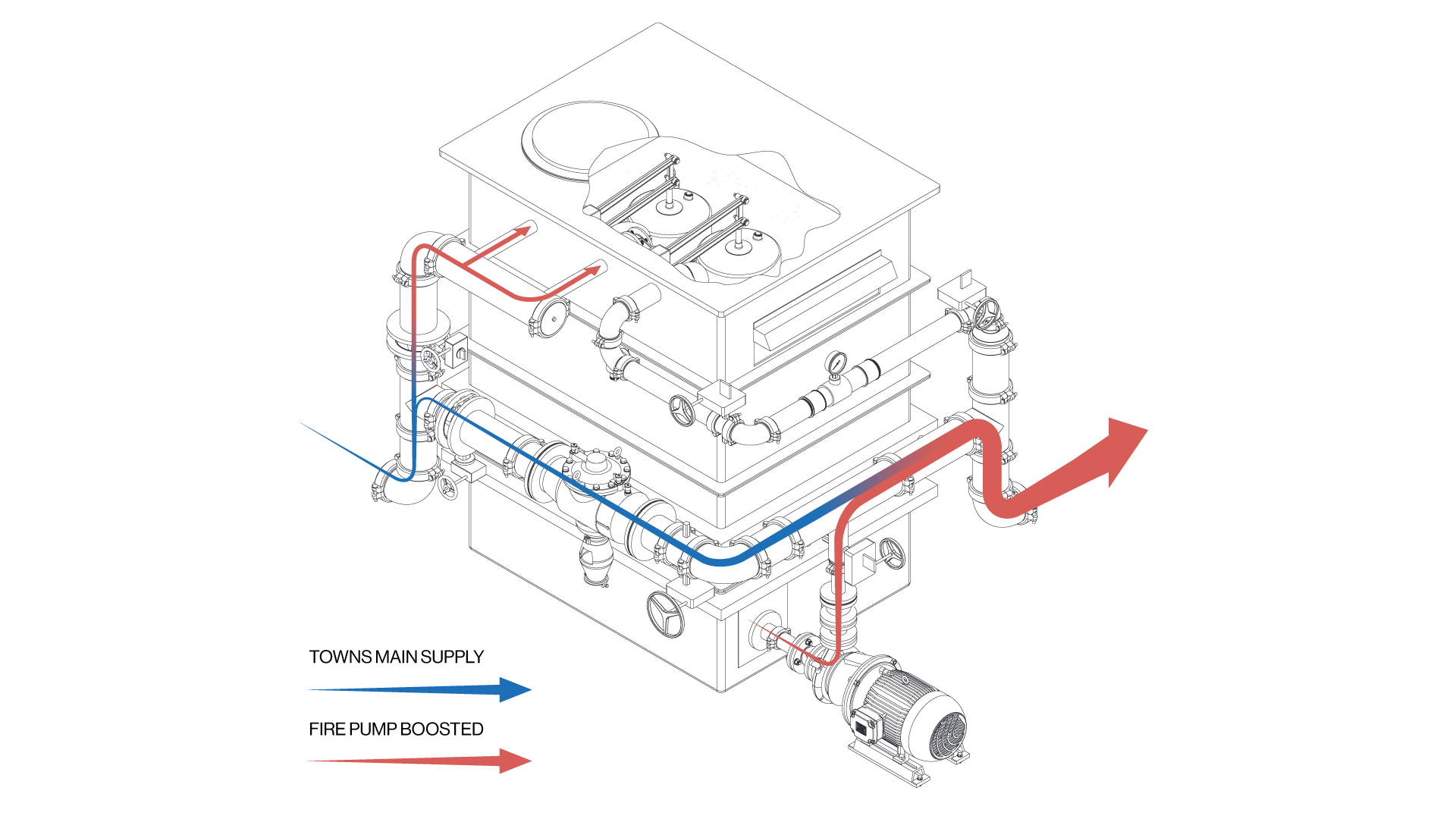

How it Works

Under normal operating conditions the sprinkler system is supplied via the town-mains. The blue route shows water from the town-mains passing through the RPZ and supplying the sprinkler system. Should the town-mains supply drop below the required pressure, the red route is automatically initiated. The pump is activated, drawing water from the AVC (Anti Vacuum Chamber). The town main then refills the AVC via the high capacity float valves.

Pressurecheck is always able to maintain the correct system operating pressure even when mains pressure is unreliable.

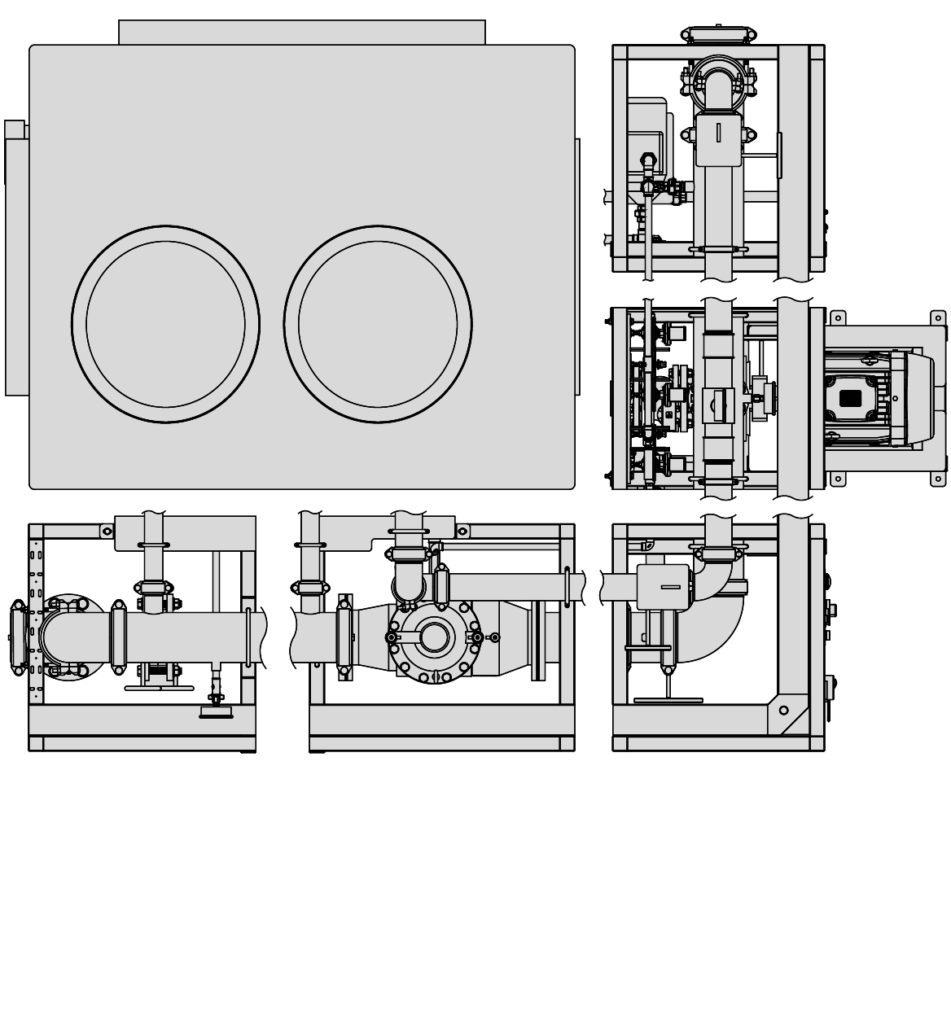

Modular Design

Our Pressurechecks come pre-configured to your buildings requirements, rated at either OH1, OH2 or OH3 hazard classification with a 15m, 30m or 45m rated fire pump determined by the highest sprinkler head on the installation. The unit is pre-wired and assembled in our factory, fully tested and can then be disassembled into separate sections for delivery to site and easy on-site installation.

SIZE

The Pressurecheck unit and its compact design takes up a floor space of approximately 3.5×3.5 metres with a ceiling height of 3 metres depending on the system configuration.

System Benefits

Space saving, Pressurecheck roughly takes up two car parking spaces, ideal for buildings with limited access or space.

With its modular design Pressurecheck can be broken down into parts for easy delivery and positioning in-situ (each part fits through a standard size door).

Pressurecheck is BS EN12845 compliant, and WRAS approved. Utilises LPCB approved components.

It’s unique plug-and-play design means that installation time and overall costs are dramatically reduced.

Pressurecheck is factory assembled & tested, simplifying project planning, installation and commissioning stages.

No new building/or pump house is required giving massive savings in construction materials, multiple site visits, building waste and disruption.

Compliant Pressures

Fire protection regulations specify that sprinkler systems must be supplied at a minimum pressure appropriate to the fire risk. Any reduction in town main pressure can render a fire protection system non-compliant. Pressurecheck boosts the sprinkler system pressure in situations where the towns-mains pressure is unsuitable and has been designed as an engineering solution to meet code standards (clause 9.2 of BS EN12845:2015).

Pressurecheck has a WRAS approved back-flow prevention system with a reduced pressure zone (RPZ), this means that no water that enters the sprinkler system will be able to contaminate the drinking water supply.

Approvals

Every Pressurecheck is fully assembled, wired and tested before it leaves the factory. Assembled in a tightly controlled manufacturing environment, every model is subjected to a set programme of stringent quality inspections. The unit is fully air and water tested before arriving on-site and because all the wiring has been completed in-house, the unit arrives ready for installation.

Pressurecheck incorporates LPCB and WRAS compliant components. All the pipes and components are safely protected and supported by five purpose-built, corrosion resistant steel frames. Each frame has been coated using a thermoplastic powder to ensure it’s fully protected to operate in damp or hazardous environments.

WE ARE HERE TO HELP

Looking for a way to boost the water supply to your sprinklers?

For more infomation, please fill out the form or send an email to info@projectfire.co.uk

Featured FAQs

How big is Pressurecheck?

Presurecheck is roughly 3.4m long by 2.3m wide by 2.3m high. It is made up of five principle frames and a sectional tank (AVC) which means that it can be broken down into sections small enough to fit through a standard doorway. This makes for easy delivery and installation in tight spaces. Please contact us for a full list of prerequisites including require access space around the unit.

Is Pressurecheck approved?

Pressurecheck uses suitability approved components such as WRAS approved RPZ and butterfly valves and LPCB approved fire pump and signalling. It is designed to be compliant with WRAS regulations and BSEN 12845 code standards.

What else is required for Pressurecheck installation?

There are various additional requirement to ensure that Pressurecheck will work correctly and reliability, please contact us for a full list of prerequisites including space, plinth/mounting surface, electrical, temperature, drainage and town main connection.

What is Pressurecheck?

Pressurecheck is a town main boosting system designed for automatic fire sprinkler systems. It boosts town main pressure using a WRAS compliant methodology, to facilitate the use of a town main supply where otherwise it would not be suitable. Pressurecheck is factory assembled, checked and tested before being delivered to site as a complete unit or in sections.

Where can Pressurecheck be used?

As an engineered solution, Pressurecheck is not limited to particular applications but has most commonly been used for retro-fit applications where water pressure from the existing town main connection was not longer suitable. Other applications for Pressurecheck include car parks and small commercial areas of a mixed use residential project and new build projects where space for a traditional water storage tanks is ruled out.