Zonecheck is simple and sustainable solution for performing sprinkler system flow-switch tests.

Flow-switches installed on a sprinkler system are required to be tested on a quarterly basis, Conventionally during a routine test, water is discharged from the down stream end of the pipe, causing a drop in the pressure. This pressure difference across the flow-switch generates a water flow causing the flow-switch to operate.

Our Zonecheck system is the modern way to carry out this important test quickly, efficiently and inexpensively saving 100% of the water normally discharged to waste. Zonecheck simplifies testing by re-circulating the water within the pipe around the flow-switch, to simulate the flow of one sprinkler head in operation, regardless of where the Zonecheck is installed or located on the system. Zonecheck is simple and easy to use, requiring no specialist skills and this flow-switch test system can be operated at any time. It does not require evacuation of the building and therefore has no effect on normal functioning of the building.

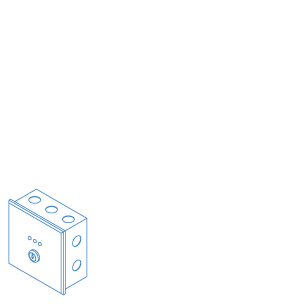

Key-switch

We have re-designed our key-switch to include a new monitoring function for a local valve. The new key-switch now detects whether a connected monitored valve is left in the correct position. Electrical engineers can then take an additional fire signal from the flow-switch and an additional fault signal from the monitored valve onwards to a centralised alarm system.

“For a building with 50 flow-switches Zonecheck saves 64,000 liters of water a year. Also, as there is no water discharge, no fire pumps run to refill the system saving fuel and energy.”

System

Benefits

With Zonecheck testing is easy. A fully code compliant test can be carried out via a simple key-switch.

Zonecheck is 100% water saving. It also indirectly save energy normally used to run large fire pumps to refill the system.

With Zonecheck, as no water is discharged, testing is easy, takes less time and requires no additional manpower.

Remote testing can be executed from a convenient location via the remote key-switch.

Zonecheck’s method of testing is the only way to accurately test to BS EN12845 code standards and only uses LPCB approved components.

Reduced maintenance, Zonecheck recirculates water within the pipe work reducing leaks and no fire pumps are run as a result of testing.

Models

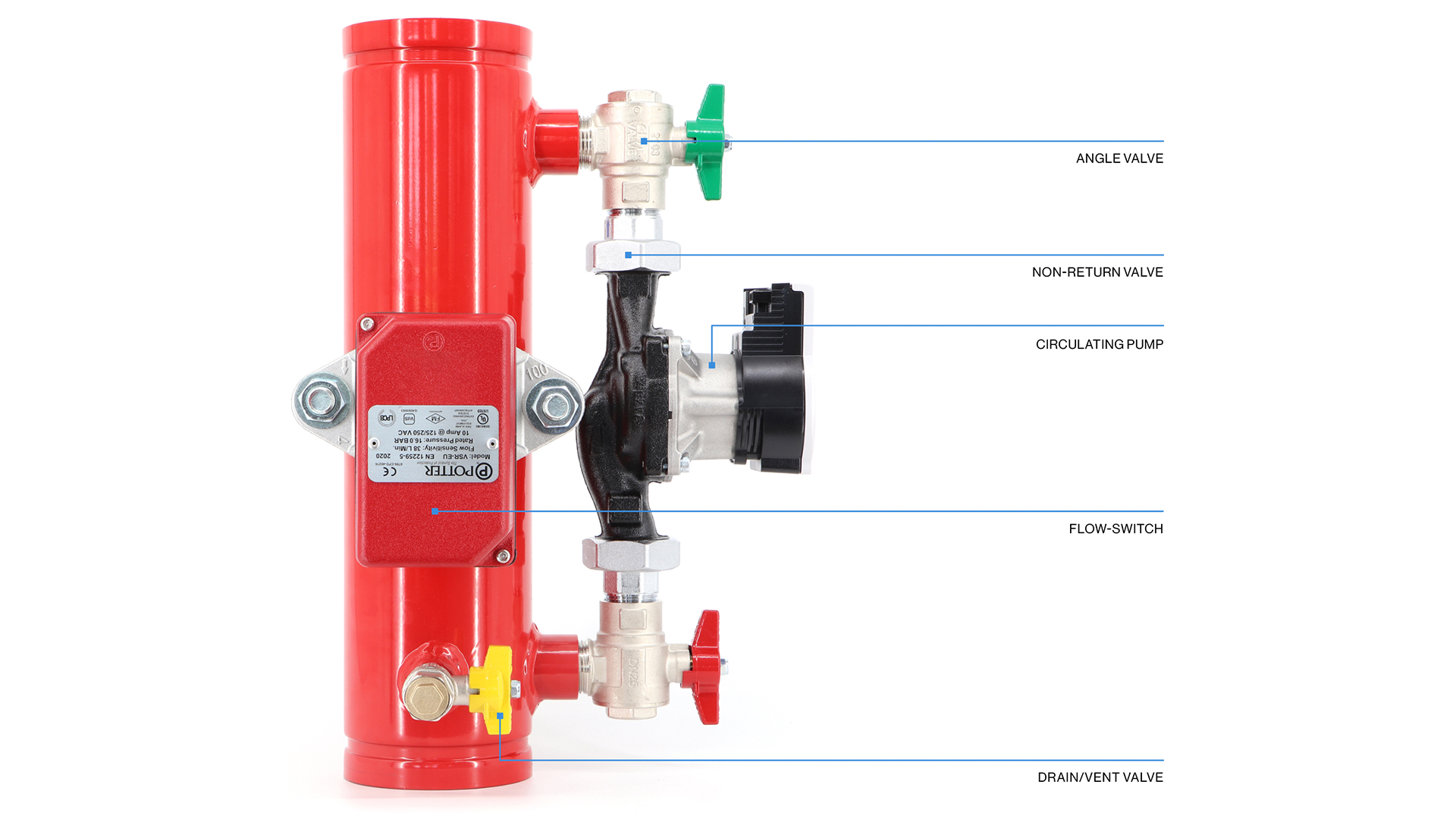

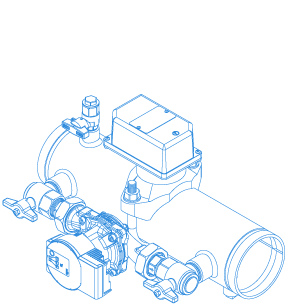

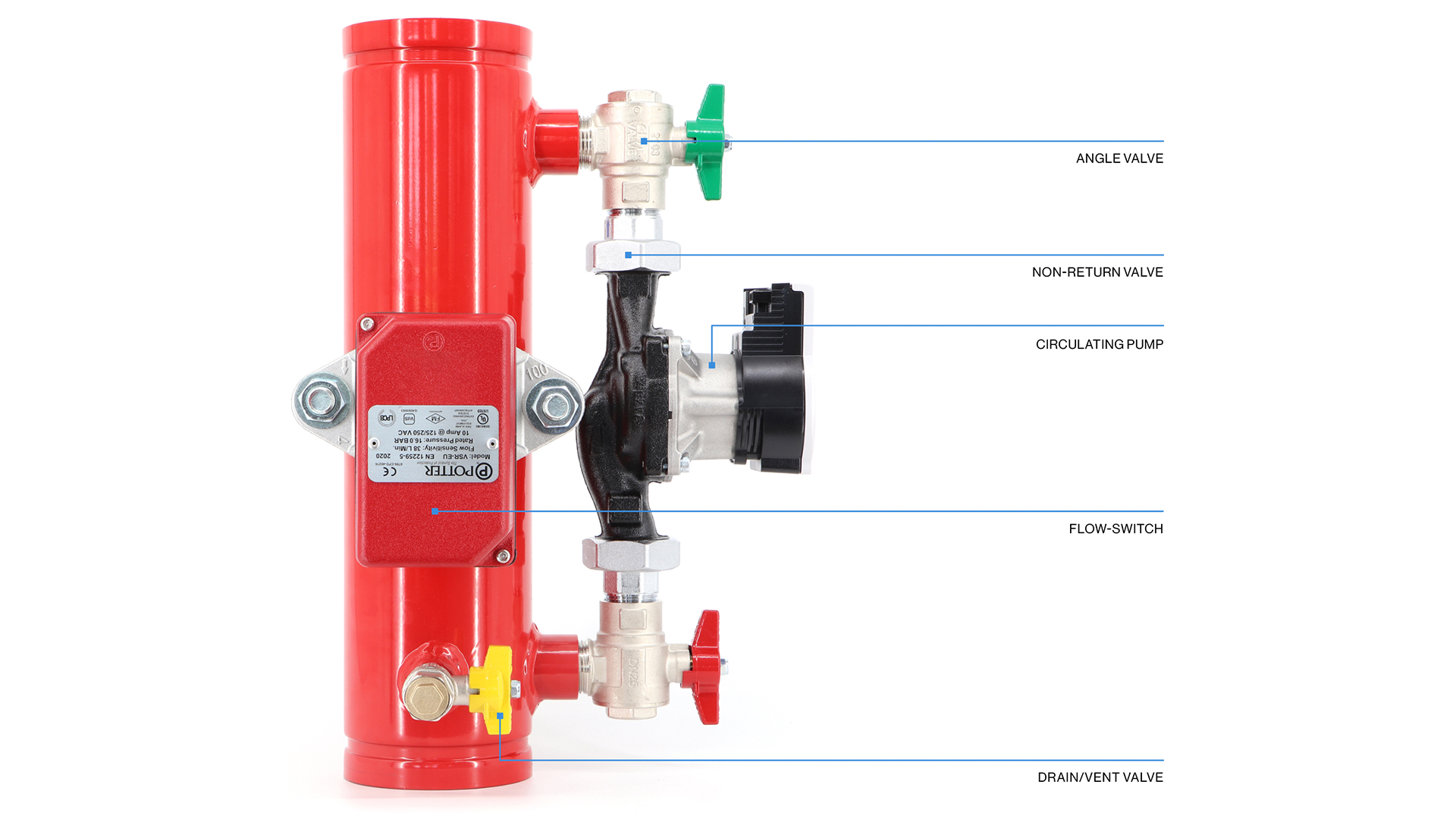

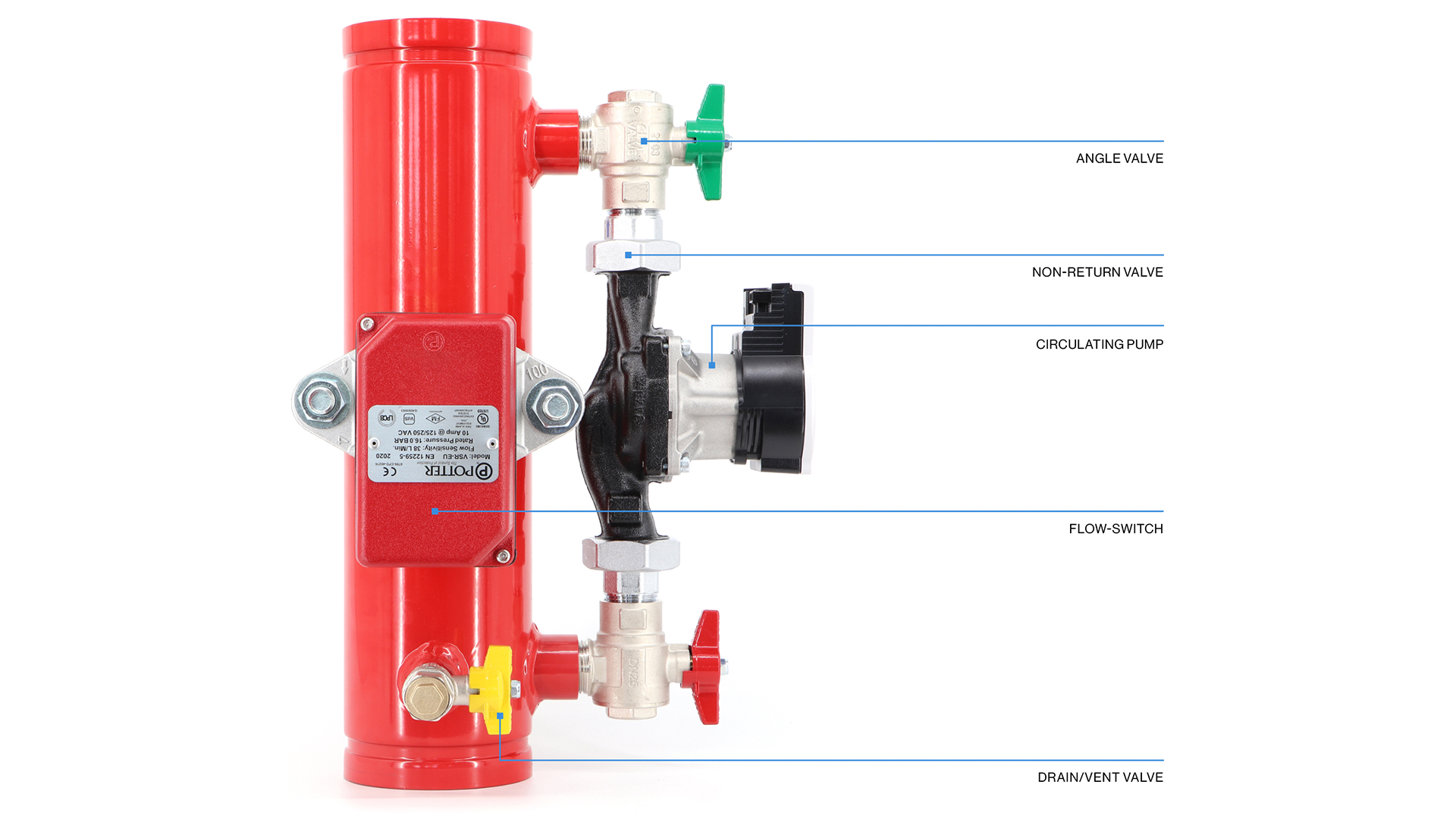

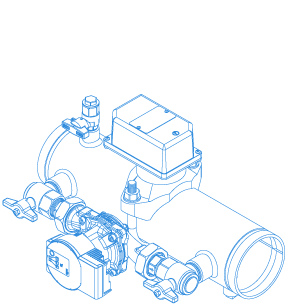

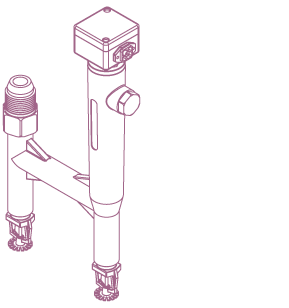

Zonecheck

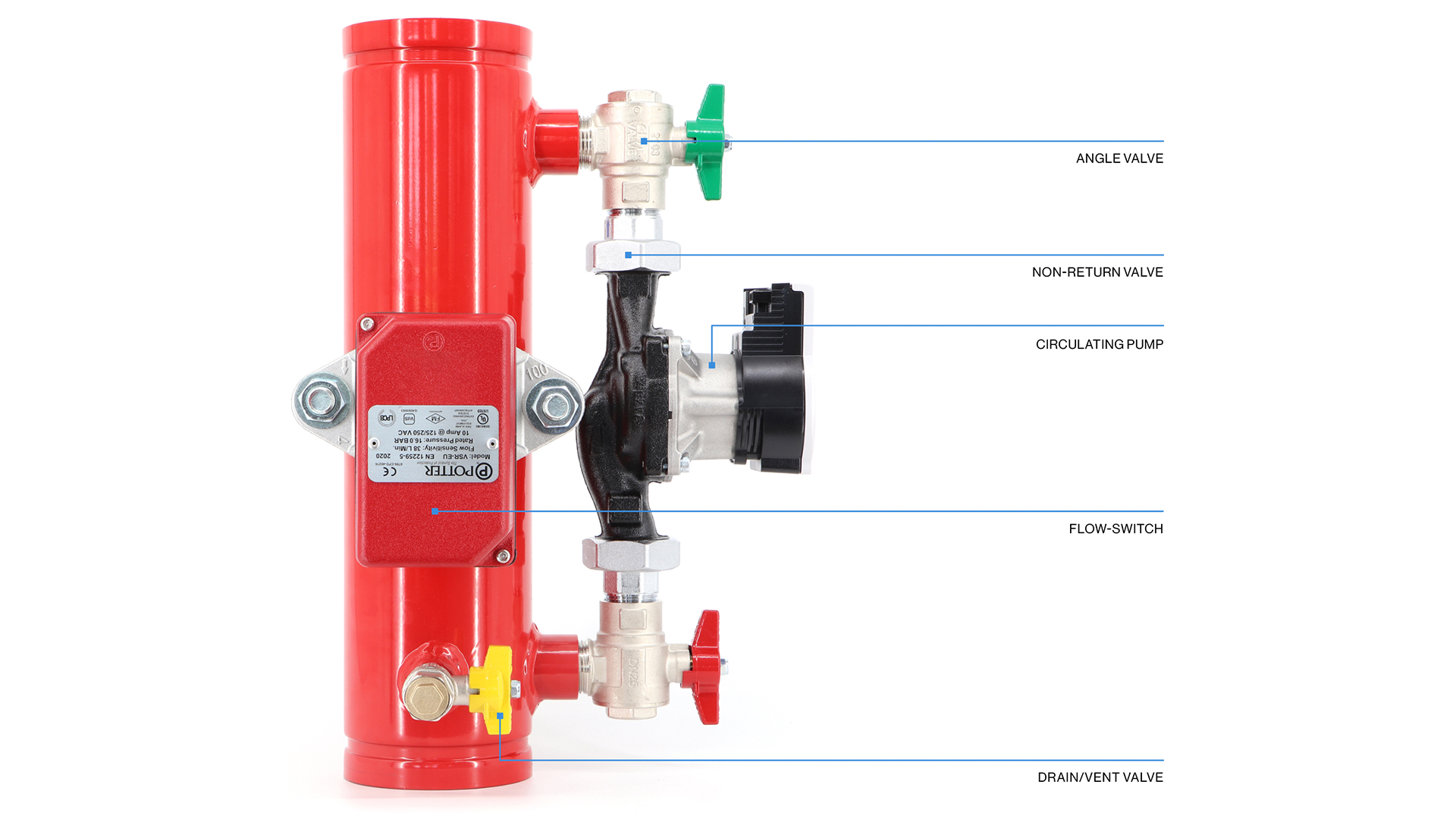

Automatic flow-switch tester, circulates water around the flow-switch so there is no need to discharge water. Comes in various models including Galvanised manifold.

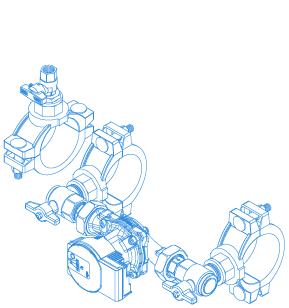

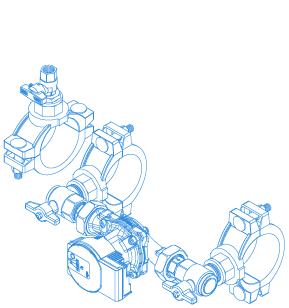

Zonecheck Retro-fit

For retro-fit applications, fits around an existing flow-switch and circulates water around the it so there is no need to discharge water.

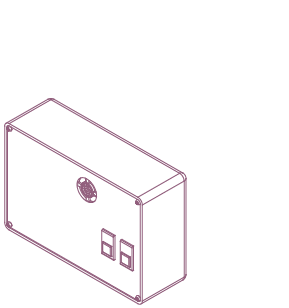

Key-switch

From the key-switch you can initiate a compliant test remotely simply by turning the key.

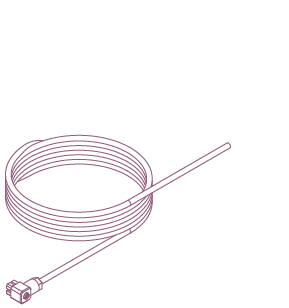

Pre-wired Loom

Pre-wired key-switch and loom for rapid site installation and commissioning.

Approvals

Zonecheck has been developed to comply with all fire sprinkler system code standards including BS EN 12845, NFPA and FM. Our Zonecheck flow-switch tester is approved by LPCB, FM, UL and VdS.

Videos

Signalling and Monitoring of Sprinkler Systems (part 1)

Signalling and Monitoring of Sprinkler Systems (part 2)

We are here to help

Want to know more about how you can simplify your testing routines?

If you want to contact a member of our team, please fill out the form or send an email to info@projectfire.co.uk

Frequently asked questions

What is a Zonecheck?

Zonecheck is the industry standard for zoned sprinkler systems to provide an easy, reliable, sustainable and cost-effective way of conducting regular flow-switch testing. A small circulating pump creates a calculated flow of water through the flow-switch to trigger it. This triggering signal is then received by the flow-switch and central alarm panel/system to verify the test was successful. The test is conducted remotely via a key-switch without the need for specialist knowledge or draining water.

Is Zonecheck approved?

Zonecheck is approved by; Loss Prevention Certification Board (LPCB), Underwriters Laboratories (UL), Factory Mutual (FM) and VdS. It is sold all over the world and also holds many country specific approvals.

How do I activate a flow-switch test?

Full installation and operating instructions can be found in our instruction booklet, please ask for a copy to be emailed to you. Please note that a flow-switch test using Zonecheck will NOT discharge any water but will likely result in a fire signal being generated. To activate a flow-switch test, turn the key in the key-switch to “self test”, at this point the “Pump Running” LED should illuminate. After a brief period (up to 60s) the “flow-switch” LED should illuminate to indicate a successful test. Record the testing being completed and return the key-switch to “stand-by” mode.

What additional wiring is required?

Our standard Zonecheck comes with a key-switch which requires mains power. The key-switch is wired to the pump and also to the flow-switch. Finally, just like a typical installation, the flow-switch also requires wiring to a central alarm panel or system. Full wiring information can be found on our data sheet and instruction booklet. We also have pre-wired Zonechecks available, please ask for more details.

What is Zonecheck Retro-fit?

Zonecheck Retro-fit is designed to be installed on a system with existing flow-switches, two mechanical tees are fitted to either side creating a closed loop so that water can be circulated around the the flow-switch that was previously installed.

Zonecheck is simple and sustainable solution for performing sprinkler system flow-switch tests.

Flow-switches installed on a sprinkler system are required to be tested on a quarterly basis, Conventionally during a routine test, water is discharged from the down stream end of the pipe, causing a drop in the pressure. This pressure difference across the flow-switch generates a water flow causing the flow-switch to operate.

Our Zonecheck system is the modern way to carry out this important test quickly, efficiently and inexpensively saving 100% of the water normally discharged to waste. Zonecheck simplifies testing by re-circulating the water within the pipe around the flow-switch, to simulate the flow of one sprinkler head in operation, regardless of where the Zonecheck is installed or located on the system. Zonecheck is simple and easy to use, requiring no specialist skills and this flow-switch test system can be operated at any time. It does not require evacuation of the building and therefore has no effect on normal functioning of the building.

Key-switch

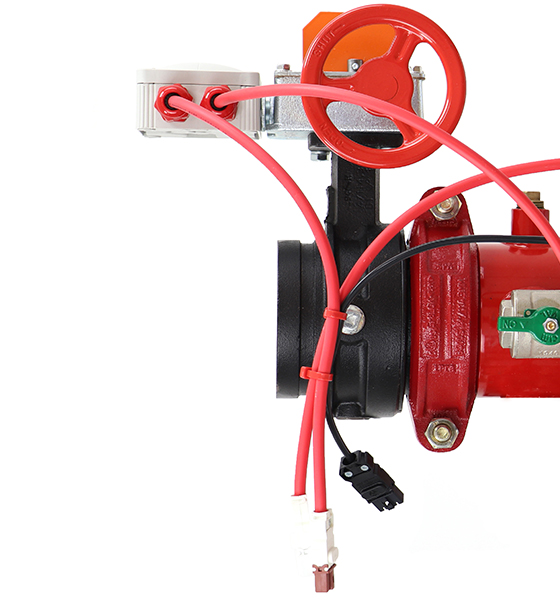

We have re-designed our key-switch to include a new monitoring function for a local valve. The new key-switch now detects whether a connected monitored valve is left in the correct position. Electrical engineers can then take an additional fire signal from the flow-switch and an additional fault signal from the monitored valve onwards to a centralised alarm system.

System

Benefits

With Zonecheck testing is easy. A fully code compliant test can be carried out via a simple key-switch.

Zonecheck is 100% water saving. It also indirectly save energy normally used to run large fire pumps to refill the system.

With Zonecheck, as no water is discharged, testing is easy, takes less time and requires no additional manpower.

Remote testing can be executed from a convenient location via the remote key-switch.

Zonecheck’s method of testing is the only way to accurately test to BS EN12845 code standards and only uses LPCB approved components.

Reduced maintenance, Zonecheck recirculates water within the pipe work reducing leaks and no fire pumps are run as a result of testing.

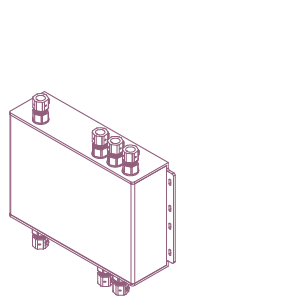

Pre-wired & Tested

Factory assembly provides consistency, accuracy and the ability to factory test units, which increase assurance and dependability once installed on site.

Zonecheck V comes fully pre-wired. The key-switch is wired to the flow-switch, pump and monitored valve via male/female connectors and is supplied with a commissioning lead. This means that the unit can be fully functionally tested and commissioned in advance of fire and fault signals being connected to a centralised system.

Approvals

Zonecheck is fully approved to LPCB, UL, VdS and FM standards. Our standard unit comes with an LPCB, VdS, UL and FM approved Victaulic Firelock 705 monitored butterfly valve.

Videos

Signalling and Monitoring of Sprinkler Systems (part 1)

Signalling and Monitoring of Sprinkler Systems (part 2)

We are here to help

Want to know more about how you can simplify your testing routines?

If you want to contact a member of our team, please fill out the form or send an email to info@projectfire.co.uk

Frequently asked questions

What is a Zonecheck?

Zonecheck is the industry standard for zoned sprinkler systems to provide an easy, reliable, sustainable and cost-effective way of conducting regular flow-switch testing. A small circulating pump creates a calculated flow of water through the flow-switch to trigger it. This triggering signal is then received by the flow-switch and central alarm panel/system to verify the test was successful. The test is conducted remotely via a key-switch without the need for specialist knowledge or draining water.

Is Zonecheck approved?

Zonecheck is approved by; Loss Prevention Certification Board (LPCB), Underwriters Laboratories (UL), Factory Mutual (FM) and VdS. It is sold all over the world and also holds many country specific approvals.

How do I activate a flow-switch test?

Full installation and operating instructions can be found in our instruction booklet, please ask for a copy to be emailed to you. Please note that a flow-switch test using Zonecheck will NOT discharge any water but will likely result in a fire signal being generated. To activate a flow-switch test, turn the key in the key-switch to “self test”, at this point the “Pump Running” LED should illuminate. After a brief period (up to 60s) the “flow-switch” LED should illuminate to indicate a successful test. Record the testing being completed and return the key-switch to “stand-by” mode.

What additional wiring is required?

Our standard Zonecheck comes with a key-switch which requires mains power. The key-switch is wired to the pump and also to the flow-switch. Finally, just like a typical installation, the flow-switch also requires wiring to a central alarm panel or system. Full wiring information can be found on our data sheet and instruction booklet. We also have pre-wired Zonechecks available, please ask for more details.

What is Zonecheck Retro-fit?

Zonecheck Retro-fit is designed to be installed on a system with existing flow-switches, two mechanical tees are fitted to either side creating a closed loop so that water can be circulated around the the flow-switch that was previously installed.

Zonecheck is simple and sustainable solution for performing sprinkler system flow-switch tests.

Flow-switches installed on a sprinkler system are required to be tested on a quarterly basis, Conventionally during a routine test, water is discharged from the down stream end of the pipe, causing a drop in the pressure. This pressure difference across the flow-switch generates a water flow causing the flow-switch to operate.

Our Zonecheck system is the modern way to carry out this important test quickly, efficiently and inexpensively saving 100% of the water normally discharged to waste. Zonecheck simplifies testing by re-circulating the water within the pipe around the flow-switch, to simulate the flow of one sprinkler head in operation, regardless of where the Zonecheck is installed or located on the system. Zonecheck is simple and easy to use, requiring no specialist skills and this flow-switch test system can be operated at any time. It does not require evacuation of the building and therefore has no effect on normal functioning of the building.

Key-switch

We have re-designed our key-switch to include a new monitoring function for a local valve. The new key-switch now detects whether a connected monitored valve is left in the correct position. Electrical engineers can then take an additional fire signal from the flow-switch and an additional fault signal from the monitored valve onwards to a centralised alarm system.

System

Benefits

With Zonecheck testing is easy. A fully code compliant test can be carried out via a simple key-switch.

Zonecheck is 100% water saving. It also indirectly save energy normally used to run large fire pumps to refill the system.

With Zonecheck, as no water is discharged, testing is easy, takes less time and requires no additional manpower.

Remote testing can be executed from a convenient location via the remote key-switch.

Zonecheck’s method of testing is the only way to accurately test to BS EN12845 code standards and only uses LPCB approved components.

Reduced maintenance, Zonecheck recirculates water within the pipe work reducing leaks and no fire pumps are run as a result of testing.

Models

Zonecheck

Automatic flow-switch tester, circulates water around the flow-switch so there is no need to discharge water. Comes in various models including Galvanised manifold.

Zonecheck Retro-fit

For retro-fit applications, fits around an existing flow-switch and circulates water around the it so there is no need to discharge water.

Key-switch

From the key-switch you can initiate a compliant test remotely simply by turning the key.

Pre-wired Loom

Pre-wired key-switch and loom for rapid site installation and commissioning.

Approvals

Zonecheck is fully approved to LPCB, UL, VdS and FM standards. Our standard unit comes with an LPCB, VdS, UL and FM approved Victaulic Firelock 705 monitored butterfly valve.

Videos

Signalling and Monitoring of Sprinkler Systems (part 1)

Signalling and Monitoring of Sprinkler Systems (part 2)

We are here to help

Want to know more about how you can simplify your testing routines?

If you want to contact a member of our team, please fill out the form or send an email to info@projectfire.co.uk

Frequently asked questions

What is a Zonecheck?

Zonecheck is the industry standard for zoned sprinkler systems to provide an easy, reliable, sustainable and cost-effective way of conducting regular flow-switch testing. A small circulating pump creates a calculated flow of water through the flow-switch to trigger it. This triggering signal is then received by the flow-switch and central alarm panel/system to verify the test was successful. The test is conducted remotely via a key-switch without the need for specialist knowledge or draining water.

Is Zonecheck approved?

Zonecheck is approved by; Loss Prevention Certification Board (LPCB), Underwriters Laboratories (UL), Factory Mutual (FM) and VdS. It is sold all over the world and also holds many country specific approvals.

How do I activate a flow-switch test?

Full installation and operating instructions can be found in our instruction booklet, please ask for a copy to be emailed to you. Please note that a flow-switch test using Zonecheck will NOT discharge any water but will likely result in a fire signal being generated. To activate a flow-switch test, turn the key in the key-switch to “self test”, at this point the “Pump Running” LED should illuminate. After a brief period (up to 60s) the “flow-switch” LED should illuminate to indicate a successful test. Record the testing being completed and return the key-switch to “stand-by” mode.

What additional wiring is required?

Our standard Zonecheck comes with a key-switch which requires mains power. The key-switch is wired to the pump and also to the flow-switch. Finally, just like a typical installation, the flow-switch also requires wiring to a central alarm panel or system. Full wiring information can be found on our data sheet and instruction booklet. We also have pre-wired Zonechecks available, please ask for more details.

What is Zonecheck Retro-fit?

Zonecheck Retro-fit is designed to be installed on a system with existing flow-switches, two mechanical tees are fitted to either side creating a closed loop so that water can be circulated around the the flow-switch that was previously installed.

A compact water supply, designed to boost your system back into full compliance.

Pressurecheck is our highly engineered compact water supply solution designed to bring your sprinkler system back into full compliance.

Taking up roughly two car parking spaces, Pressurecheck is a very compact alternative to a pump and tank system. Pressurecheck works by drawing water from the town-mains supply to feed a sprinkler system which cannot reliably meet the minimum pressures required for a specific risk. It can also be used as a direct alternative to traditional pump and tanks systems, increasing valuable revenue space and streamlining installation.

As Pressurecheck is built and fully tested in our factory, it can be delivered and installed quickly with minimal disruption. Offering a unique plug-and-play design means that installation time and overall costs are dramatically reduced.

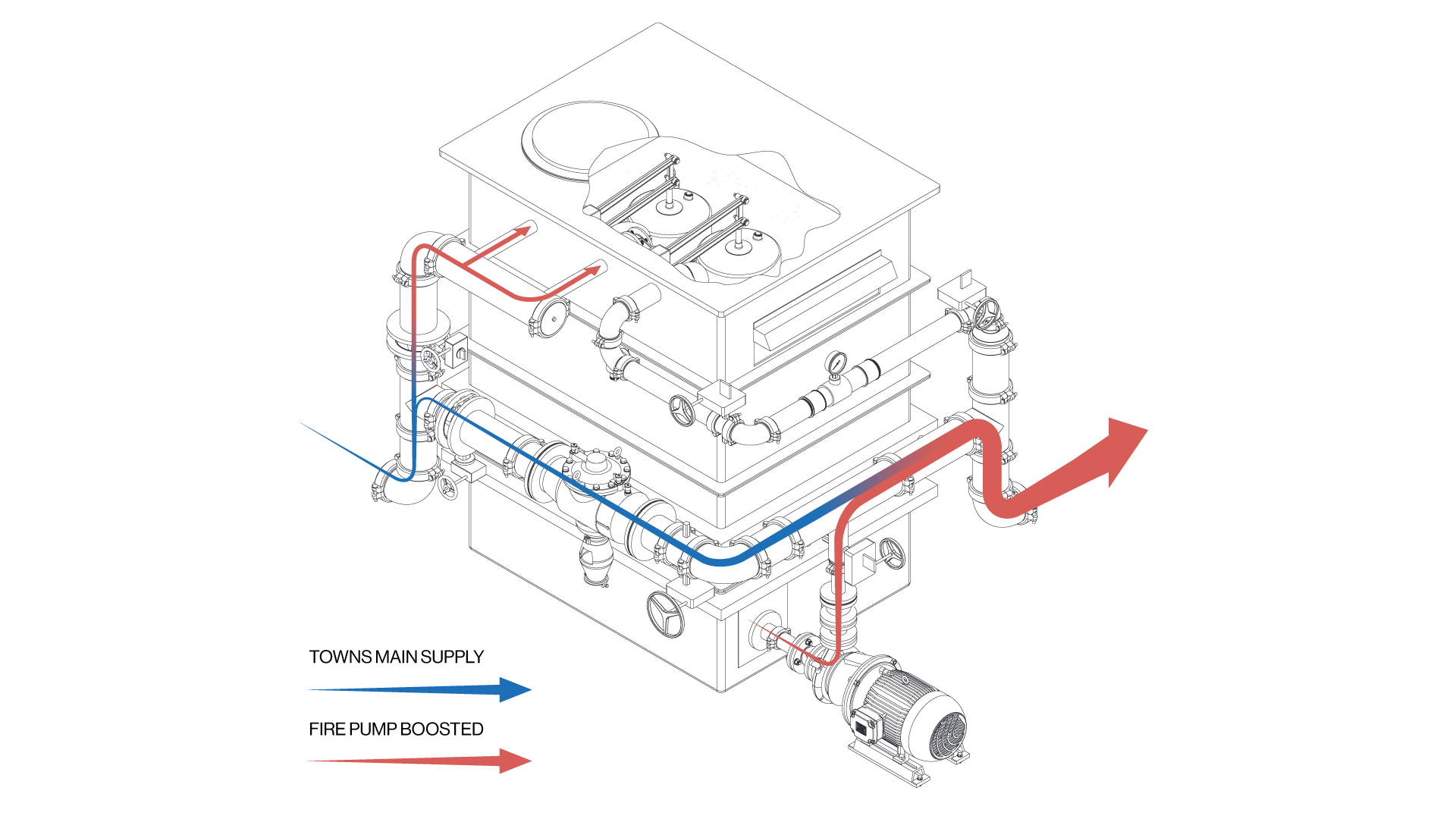

How it Works

Under normal operating conditions the sprinkler system is supplied via the town-mains. The blue route shows water from the town-mains passing through the RPZ and supplying the sprinkler system. Should the town-mains supply drop below the required pressure, the red route is automatically initiated. The pump is activated, drawing water from the AVC (Anti Vacuum Chamber). The town main then refills the AVC via the high capacity float valves.

Pressurecheck is always able to maintain the correct system operating pressure even when mains pressure is unreliable.

Modular Design

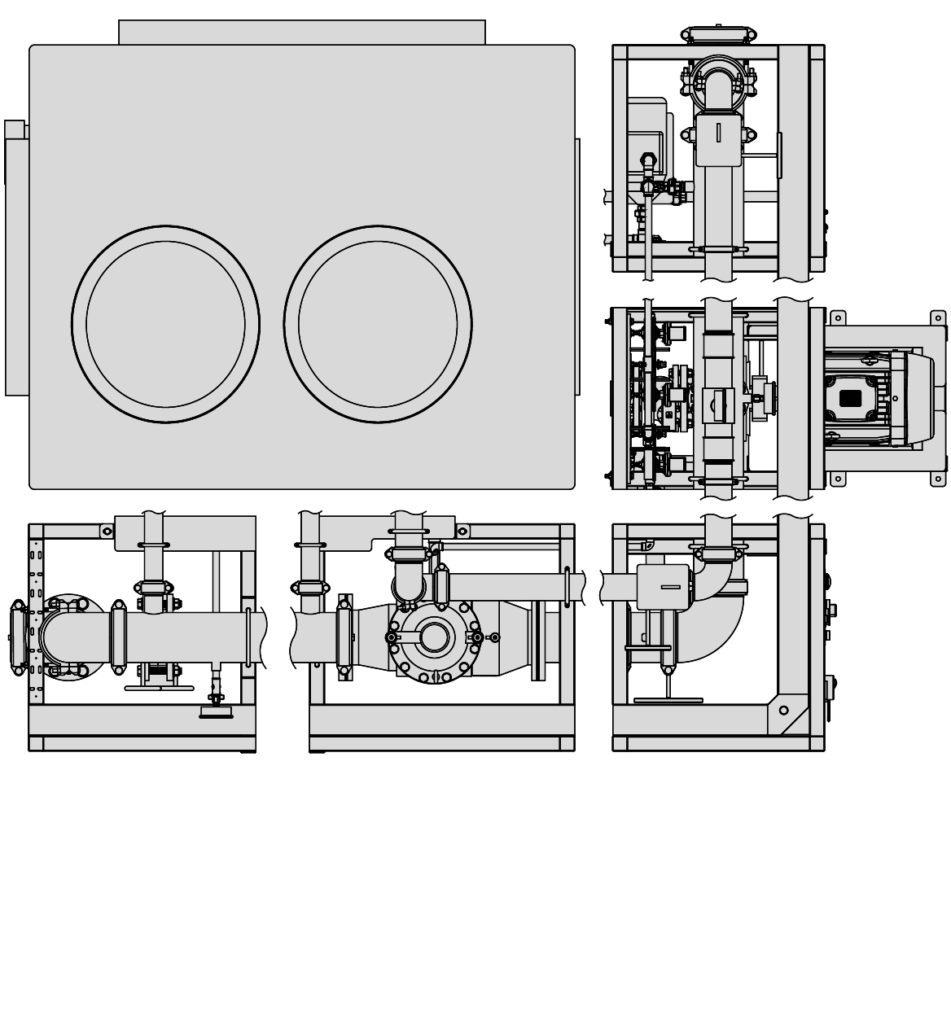

Our Pressurechecks come pre-configured to your buildings requirements, rated at either OH1, OH2 or OH3 hazard classification with a 15m, 30m or 45m rated fire pump determined by the highest sprinkler head on the installation. The unit is pre-wired and assembled in our factory, fully tested and can then be disassembled into separate sections for delivery to site and easy on-site installation.

SIZE

The Pressurecheck unit and its compact design takes up a floor space of approximately 3.5×3.5 metres with a ceiling height of 3 metres depending on the system configuration.

System Benefits

Space saving, Pressurecheck roughly takes up two car parking spaces, ideal for buildings with limited access or space.

With its modular design Pressurecheck can be broken down into parts for easy delivery and positioning in-situ (each part fits through a standard size door).

Pressurecheck is BS EN12845 compliant, and WRAS approved. Utilises LPCB approved components.

It’s unique plug-and-play design means that installation time and overall costs are dramatically reduced.

Pressurecheck is factory assembled & tested, simplifying project planning, installation and commissioning stages.

No new building/or pump house is required giving massive savings in construction materials, multiple site visits, building waste and disruption.

Compliant Pressures

Fire protection regulations specify that sprinkler systems must be supplied at a minimum pressure appropriate to the fire risk. Any reduction in town main pressure can render a fire protection system non-compliant. Pressurecheck boosts the sprinkler system pressure in situations where the towns-mains pressure is unsuitable and has been designed as an engineering solution to meet code standards (clause 9.2 of BS EN12845:2015).

Pressurecheck has a WRAS approved back-flow prevention system with a reduced pressure zone (RPZ), this means that no water that enters the sprinkler system will be able to contaminate the drinking water supply.

Approvals

Every Pressurecheck is fully assembled, wired and tested before it leaves the factory. Assembled in a tightly controlled manufacturing environment, every model is subjected to a set programme of stringent quality inspections. The unit is fully air and water tested before arriving on-site and because all the wiring has been completed in-house, the unit arrives ready for installation.

Pressurecheck incorporates LPCB and WRAS compliant components. All the pipes and components are safely protected and supported by five purpose-built, corrosion resistant steel frames. Each frame has been coated using a thermoplastic powder to ensure it’s fully protected to operate in damp or hazardous environments.

WE ARE HERE TO HELP

Looking for a way to boost the water supply to your sprinklers?

For more infomation, please fill out the form or send an email to info@projectfire.co.uk

Featured FAQs

How big is Pressurecheck?

Presurecheck is roughly 3.4m long by 2.3m wide by 2.3m high. It is made up of five principle frames and a sectional tank (AVC) which means that it can be broken down into sections small enough to fit through a standard doorway. This makes for easy delivery and installation in tight spaces. Please contact us for a full list of prerequisites including require access space around the unit.

Is Pressurecheck approved?

Pressurecheck uses suitability approved components such as WRAS approved RPZ and butterfly valves and LPCB approved fire pump and signalling. It is designed to be compliant with WRAS regulations and BSEN 12845 code standards.

What else is required for Pressurecheck installation?

There are various additional requirement to ensure that Pressurecheck will work correctly and reliability, please contact us for a full list of prerequisites including space, plinth/mounting surface, electrical, temperature, drainage and town main connection.

What is Pressurecheck?

Pressurecheck is a town main boosting system designed for automatic fire sprinkler systems. It boosts town main pressure using a WRAS compliant methodology, to facilitate the use of a town main supply where otherwise it would not be suitable. Pressurecheck is factory assembled, checked and tested before being delivered to site as a complete unit or in sections.

Where can Pressurecheck be used?

As an engineered solution, Pressurecheck is not limited to particular applications but has most commonly been used for retro-fit applications where water pressure from the existing town main connection was not longer suitable. Other applications for Pressurecheck include car parks and small commercial areas of a mixed use residential project and new build projects where space for a traditional water storage tanks is ruled out.

Peace of mind when installing sprinklers to water sensitive areas.

Gemini is a pre-action sprinkler head that effectively eliminates accidental release. The unit acts as a ‘double-knock’ system and will only release water when both heads have been activated.

Unintentional activation of a sprinkler system is very unlikely but unfortunately cannot be ignored. This often means that sensitive areas of a building where accidental release would cause severe water damage are left unprotected. Alternative systems such as pre-action installations or stand-alone gaseous protection have distinct drawbacks.

Pre-action installations are costly to install and maintain due to the additional equipment required such as additional pipework, detectors, releasing panel, dedicated alarm valve and air compressor. Pre-action installations are also not preferred for life safety applications. Gaseous systems have similar disadvantages and also take up additional space to store gas cylinders.

-

Gemini Brochure

Download

System Features

Cost efficient pre-action system requiring no specialist equipment or maintenance requirements.

Simple installation, uses same connections as traditional piping systems.

Gemini is easy to maintain, other pre-actions systems are expensive and require specialist maintenance.

No accidental discharge, additional safeguard when protecting water-sensitive equipment.

A sustainable, environmentally friendly alternative to gaseous systems.

Easily integrated into existing sprinkler systems with wet or dry pipework.

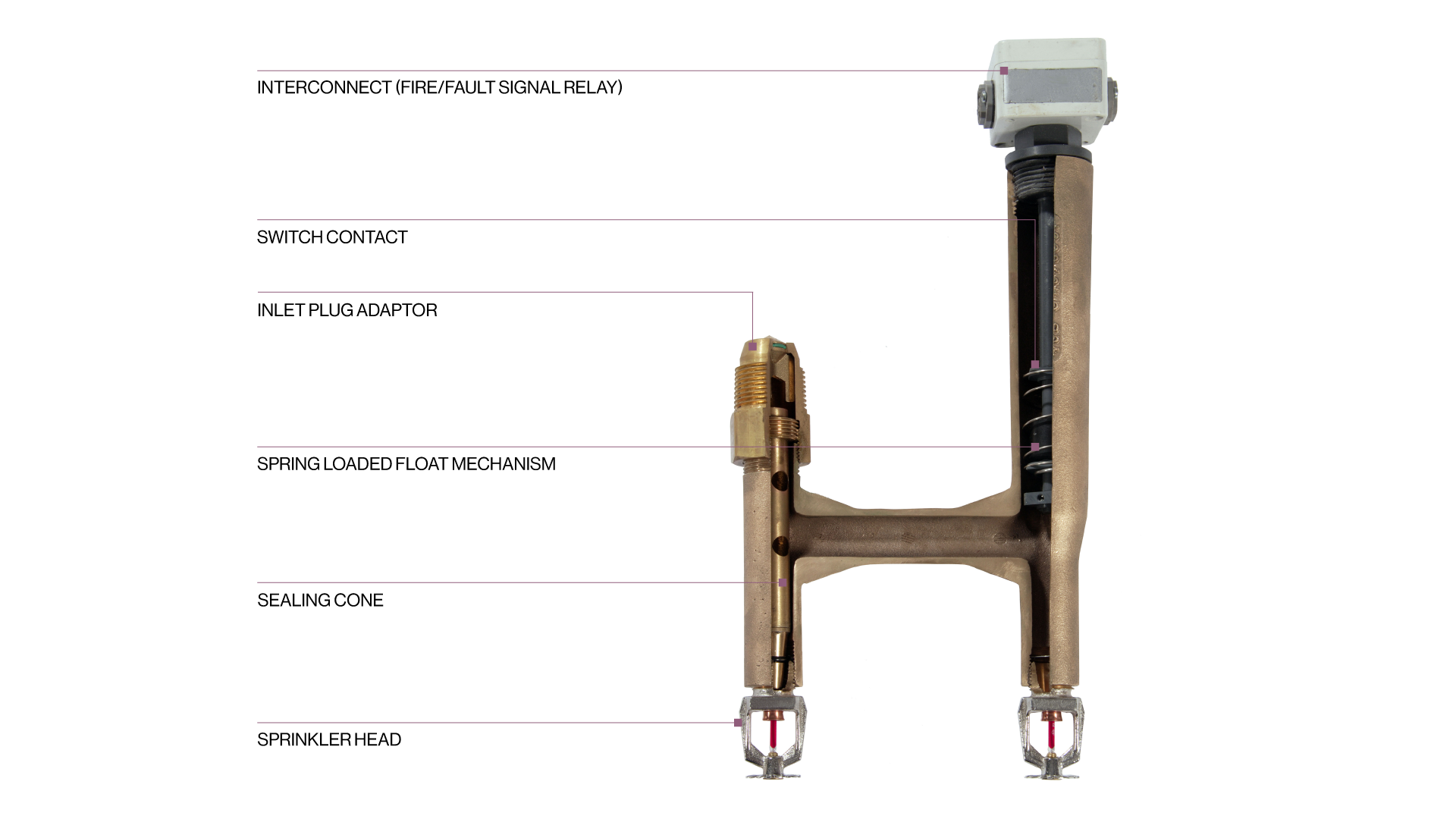

The Gemini System

When water-sensitive areas within a building (such as a server room) is to be protected, the use of Gemini pre-action sprinklers represents a simple and cost effective solution. These special sprinklers can be simply connected to the existing or planned sprinkler pipework to provide ‘double-knock ‘safety against unwanted water discharge, whilst offering the same fire protection as standard sprinkler heads.

With this system, the quick response heads operate in such a way that the first head to activate acts as a detector and will relay an alarm condition signal, alerting the building owner or facilities management. The second integrated head is engineered to act as a normal sprinkler head and discharge water on activation.

In an actual fire condition, both heads will activate and water will be discharged from the right sprinkler head only (see cut away diagram). This design minimises any delay and provides the normal benefits associated with reliable wet fire suppression systems and life safety quick response heads. In the case of only one head being activated by accident, no water is released.

System Components

Gemini sprinkler head

The pre-action sprinkler unit consists of a cast housing with two separately arranged sprinklers. The head is mechanically installed using a union coupling.

DSZ 3000 monitoring panel

The monitoring panel can monitor one or multiple linked Gemini heads and show their operating status.

Interconnect cable

Interconnect cables are used to connect several Gemini sprinkler head units together in parallel. A special end-of-line cable is used for the last unit in the run which, is then connected to the Gemini monitoring panel.

IMM

A Gemini system can be connected to an IMM and monitored via our Zonecheck Addressable controller (see Zonecheck Addressable brochure).

Approvals

The Gemini sprinkler head is approved to VdS standards. Gemini facilitates easy compliance with LPC TB206 to sprinkler protect all areas of commercial buildings over 30m tall.

We are here to help

Need to project your comms rooms but worried about water damage?

If you want to contact a member of our team, please fill out the form or send an email to info@projectfire.co.uk

FAQs

Is Gemini approved

Gemini is currently available with VdS approval.

What is Gemini?

Gemini is a pre-action sprinkler head meaning that it has the benefits of additional protection against accidental water discharge (similar to specialised pre-action sprinkler systems) compacted into a single unit. Gemini features two sprinkler heads, both of these heads must be activated in order for water to be discharged (in a fire situation). Where just of the heads is activated, a fault alarm is generated but no water is discharged prevented accidental water release.

Where can I install Gemini?

Gemini is designed for use where water damage from sprinkler heads is a real concern but the protection that the sprinklers provide is still required/desired. Typical uses are small server rooms/electrical rooms within lager buildings such as offices, retail, hospitals and transportation hubs.

How does Gemini connect to a sprinkler system?

Gemini connects onto standard sprinkler pipework to connect onto the supplied 1” union.

Can Gemini be linked to a central fire alarm panel or BMS system?

Yes, the stand alone monitoring panel has functionality to provide a fault relay output compatible with most any panel and systems including BMS.

Closed control valves are the leading cause of sprinkler system failures, fire codes require them to be inspected routinely.

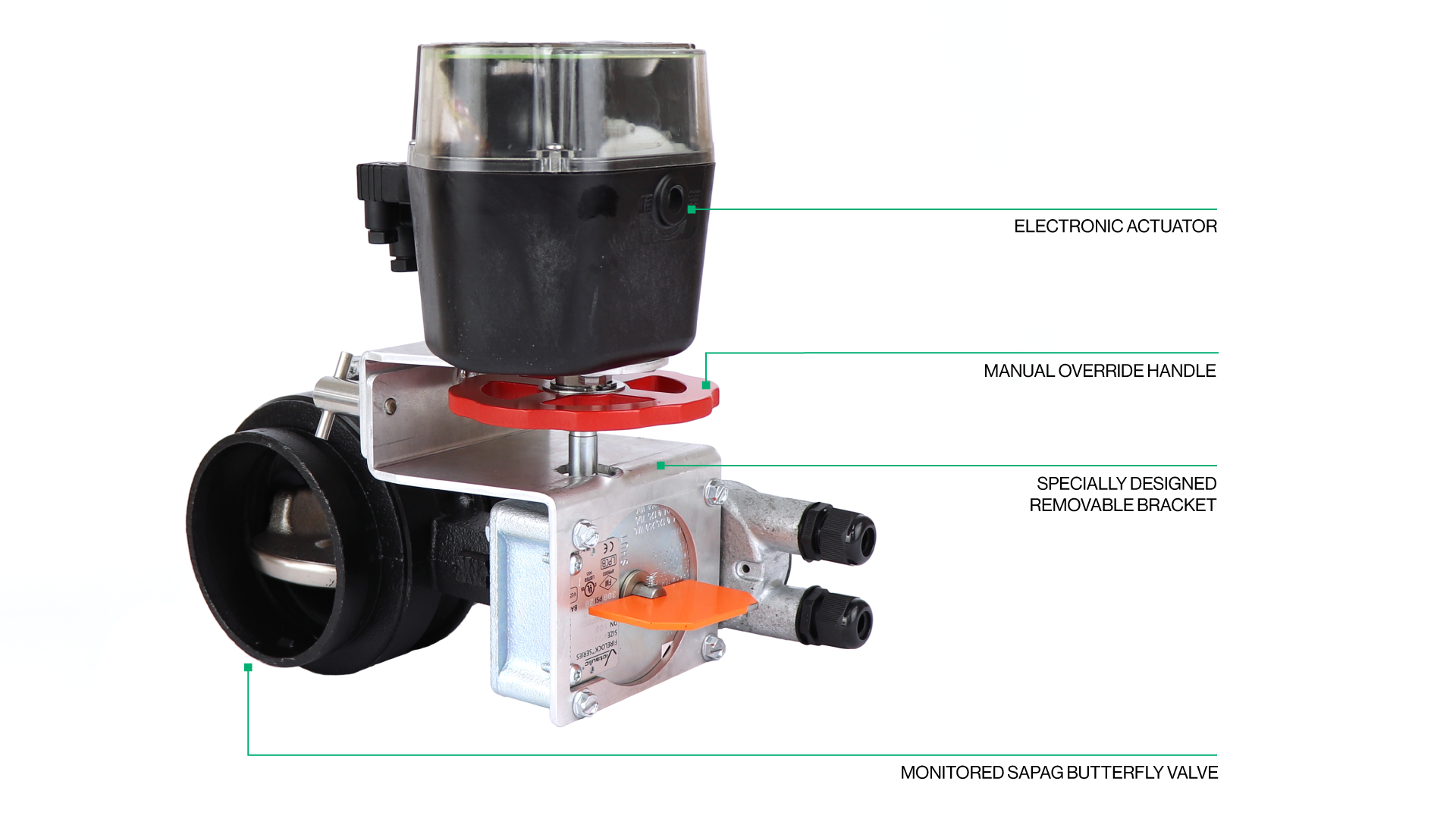

Closed control valves are the leading cause of sprinkler system failures, fire codes require them to be inspected routinely (see overleaf). Valvecheck allows the remote and automatic testing of zone valves for their correct operation and position.

We see this as a major step forward in providing automated testing and monitoring for a sprinkler system, as now with the inclusion of this functionality (combined together with our current Zonecheck system) no regular access is required to sprinkler components in remote locations in the building.

AUTOMATED TESTING

Our solution will operate and fully exercise the valve, either on a daily, weekly or monthly basis, dependant on the requirement and configuration of the Zonecheck Addressable system. During a test, the controller will constantly be monitoring the position of the valve, and is stopped at the calibrated fully closed point before being automatically opened after that. The system has the vital benefit of being a fail-safe ‘open’ actuator with an internal battery supply that will ensure that the valve is always in the open position under normal circumstances.

-

BROCHURE

Download

Zone valves must be tested quarterly but are often hard to access, and so, left unwired, untested and in the incorrect position, rendering the sprinkler system inoperable.

System benefits

Keep operational costs down with Valvecheck’s automated routine testing, reducing overall facilities management requirements.

The controller takes care of testing routines for you exercising the valve and checking for correct position.

Pro-active monitoring of a building’s isolation valves.

Easy compliance with Fire Codes and Regulations regarding the quarterly operation and exercising of stop valves (BS EN12845 20.3.2.7).

Often zone valves are positioned in difficult, hard to reach places, with Valvecheck, no regular contractor access is required to remote locations in the building.

The actuator has an internal battery that will always ensure the valve is in the open position, even in the event of power loss.

Remote Testing

Many zone valves are located at high level or behind ceiling structures, which makes the mandatory quarterly test expensive and disruptive. Forming part of our addressable system, Valvecheck automates the process of closing and opening every zone valve ensuring that the correct fault signal is received and registered.

Valvecheck consists of an electronic actuator that attaches to a standard sapag butterfly valve via a specially designed bracket. The bracket can also be retro-fitted to existing valves depending on the model and is removable in case a manual override is required.

Code Compliance

Quarterly exercising of all control valves is a requirement of BS EN12845 20.3.2.7 Stop valves and NFPA 25 N 13.3.2.1.2. Our addressable system is approved to UL standards.

Valvecheck is an add-on to our wider addressable sprinkler testing and monitoring system, and can be combined with Zonecheck to fully automate the quarterly testing of flow-switches and local zone valves. It can also be installed without the flow-switch testing option.

WE ARE HERE TO HELP

Find out more about how we can automate your sprinkler testing routines.

If you want to contact a member of our team, please fill out the form or send an email to info@projectfire.co.uk

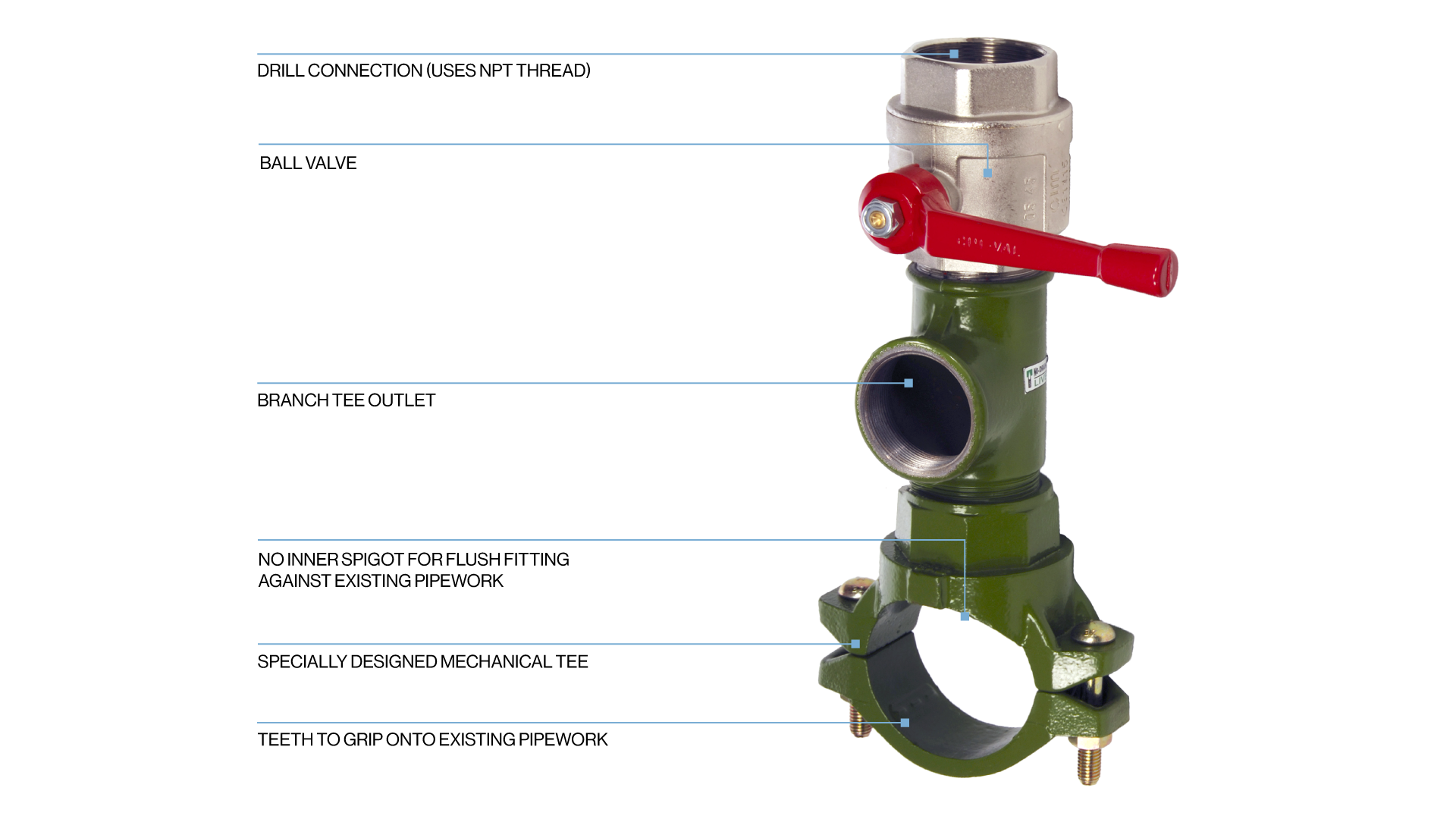

Sprinkler modifications without the added hassle, cost and time of draining down.

Livetap is a major innovation for making modifications to sprinkler systems. No drain down is required, making it the simplest, fastest and most cost effective way to make modifications while complying with all fire sprinkler system codes.

UNDER PRESSURE DRILLING

The Livetap under pressure drilling concept has been developed to address the issues that arise when planning and implementing modifications and additions to existing sprinkler systems, and modifying existing sprinkler head locations.

Livetap allows qualified engineers to undertake work on live systems, without the need to drain down. Fire protection is maintained at all times during the sprinkler works. Consequently there is no need to advise fire authorities or close the building while work is in progress, minimising business disruption.

Using Livetap ensures no dirty water discharge, no difficult backfilling and no complex downtime arrangements, with the use of Livetap an engineer could add or move a sprinkler head in under two hours.

-

BROCHURE

Download

System Benefits

NO DRAIN DOWN

There is no need to drain down the sprinkler system to make modifications with Livetap, all works can be carried out live.

SPRINKLERS REMAIN LIVE

As there is no need to drain down sprinkler protection remains live so, there is no need to notify fire authorities or insurers of any planned works.

NO ISOLATING ALARMS

There’s no need to isolate alarms, fire pumps and with no waiting around for systems to drain or recharge, sprinkler works can be done in a fraction of the time.

BUILDING REMAINS OPEN

As sprinkler protection is maintained during works, there is no need to shut down parts of the building, phase works or put additional security measures in place.

VERSATILE FITTINGS

Livetap comes with a wide range of fittings designed to make modifications and small works easier.

APPROVED

The Livetap under pressure drilling system is fully approved and meets all relevant fire code standards.

Under Pressure Drilling Training

The Livetap drilling system comprises a range of specially designed drilling equipment and accessories together with fully approved applications for small sprinkler works, system extensions and modifications. Although Livetap is a well proven and reliable system, only suitably trained and qualified personnel can use the Livetap under pressure drilling system and associated product range. Engineers are required to attend a competency training course at an approved Project Fire training facility to become certified. More information on training can be found on our website.

Livetap Applications

No Drain T

Specially designed mechanical tee engineered to provide a branch tee outlet without an in-line valve. Allows the ‘live’ installation of additional sprinklers. Available in a wide range of pipe sizes.

Kwik Drain

Using Livetap technology allows the user to quickly install a drain connector in the most beneficial location on the system without draining down.

Kwik Vent

Kwik Vent is used to vent troublesome trapped air within sprinkler pipework. This connection can also be used in conjunction with freezing equipment to modify/alter small pipework arrangements.

Drill & Toolkit

The Livetap tool boxes incorporate all the drilling equipment and accessories needed to undertake live sprinkler modifications.

Approvals

Zonecheck has been developed to comply with all fire sprinkler system code standards including BS EN 12845, NFPA and FM. Our Zonecheck flow-switch tester is approved by LPCB, FM, UL and VdS.

WE ARE HERE TO HELP

Add Livetap under pressure drilling to your arsenal.

For more infomation, please fill out the form or send an email to info@projectfire.co.uk

Featured FAQs

What is Livetap?

Livetap allows for sprinkler modifications and additions without draining down. Pipework can be drilled with the water remaining at pressure within the pipe. This has many advantages including saving a large amount of time and water.

Is Livetap approved?

Yes, we hold approvals for the system and fittings from LPCB, VdS, FM and UL. This system is the only approved method for drilling into live sprinkler pipework and has proven to be safe and reliable since it launched in the early 2000s.

What can I use Livetap for?

Livetap is compatible with our range of fittings including drain valve (Kwik Drain), sprinkler tees (No Drain T) and Zonecheck Live which allows for a Zonecheck to be fitted around an existing Zonecheck.

What do I learn on the Livetap training course?

Our training course will run through the theory behind Livetap before progressing onto dry cutting to get to grips with the equipment; once this is completed, students will move on to use Livetap on our live sprinkler system. The day finishes with instruction on how to disassemble and clean the drill before a small exam to test knowledge gained during the day.

What do I need to get started?

Toolkits and fittings are available from Project Fire Products Ltd. However, in line with approval mandates, a training course (typically one day) must be completed before purchase. Please contact us for more details.

Save hours of on-site labour and costs.

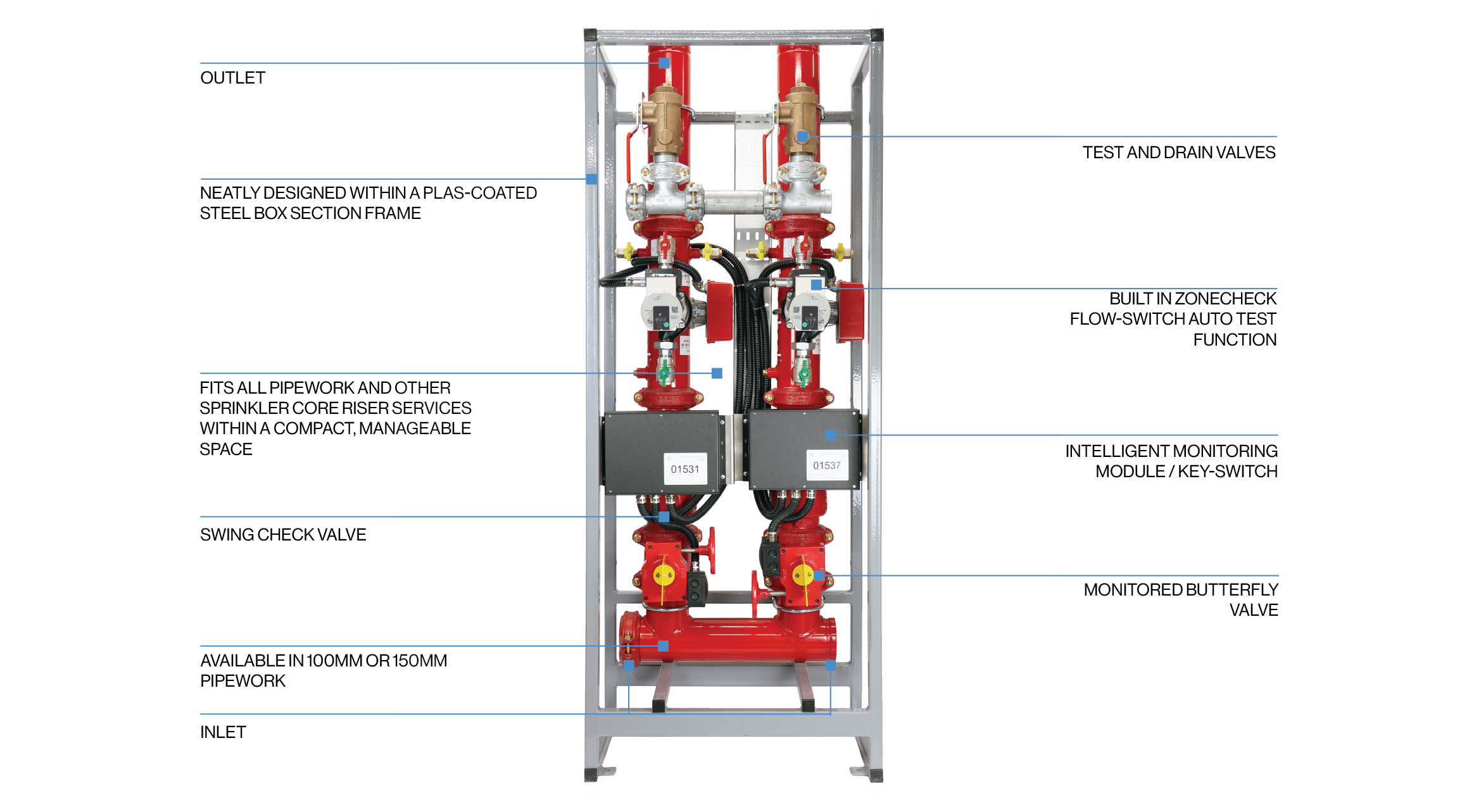

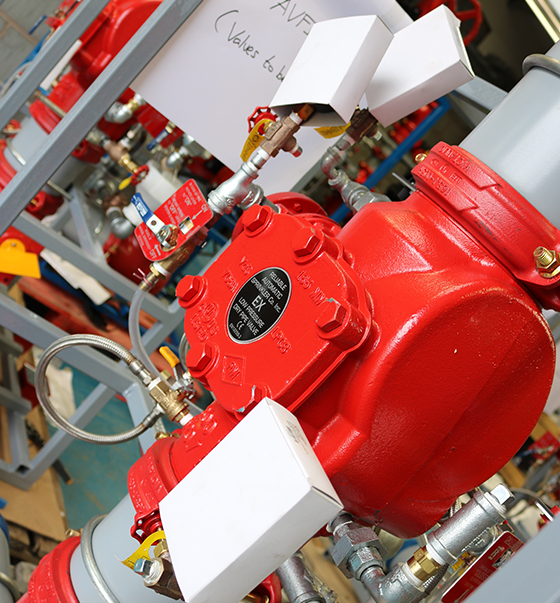

Firepods are the latest in high-tech, value engineered, plug-and-play fire protection, and is the first fully-modular sprinkler zone valve and test assembly in the industry. The product has been specifically created for architects, designers, contractors, building developers and owners to offer a solution for the procurement, installation, operation and whole life cost of sprinkler systems.

They are designed to speed up installation and incorporate automatic smart testing and monitoring facilities. Built and tested off-site, these pods provide a compact solution for risers and plant rooms.

Each Firepod comes with a smart testing facility, combine this with our addressable controller and fully automated routine testing can be fully managed from one central location. Each pod’s local Intelligent Monitoring Module (IMM) monitors it’s core components so you have up-to-the-minute feedback and status reports on the current condition of the sprinkler system. The addressable controller also provides feedback in real time of all the installed Firepods, as well as the option to monitor other sprinkler components, giving you full control over a building’s automatic fire sprinkler system. Key-switch models are available, enabling local testing at the turn of a key.

System Benefits

The plug-and-play design means that installation time, commissioning and overall costs are dramatically reduced.

Keep operational costs down with Zonecheck’s efficient method of routine testing and reduced facilities management.

Testing routines can be carried out either at the touch of a button or be fully automated.

Prelim savings of up to 36% when compared to on-site build.

Increased rental yield as a result of the narrower sprinkler riser.

Pro-active monitoring of buildings sprinkler system and components. Firepods can also be integrated into a building’s fire alarm system or BMS.

Off-site Construction

Prefabrication is an established, and proven option for larger scale cellular builds e.g. hotels, shopping malls, high-rise and the modular implementation of larger single builds, such as airports and warehousing. Factory assembly provides consistency, accuracy and the ability to factory test units, which increase assurance and dependability once installed on site.

Firepod’s standardisation and factory-detailed assembly means it’s able to offer a range of benefits from design, procurement to assembly and final commissioning. Furthermore, the composite package is offered at a discount to the traditional site installation of materials and labour, and so the collective intangible benefits provide a compelling case for its specification for cost saving on a project.

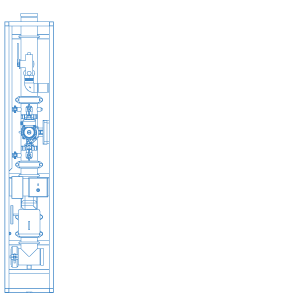

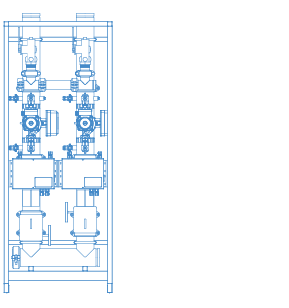

System Configurations

Single

100-150mm

A single prefabricated core riser with integrated smart testing and monitoring facilities, includes drainage lines and local zone valves. Includes LPCB, FM, UL & VdS approved Zonecheck flow-switch testing facilities.

Comes with either IMM (for automated testing) or key-switch.

Double

100-150mm

A double prefabricated core riser with integrated smart testing and monitoring facilities, includes drainage lines and local zone valves. Includes LPCB, FM, UL & VdS approved Zonecheck flow-switch testing facilities.

Comes with either IMM (for automated testing) or key-switch.

Approvals

Our addressable system is approved to UL standards and conforms with the relevant life safety requirements detailed in BS EN12845. Zonecheck is approved to LPCB, FM, UL & VdS standards. All components meet necessary approvals.

By using Firepods, on-site delivery and co-ordination issues are simplified, numerous orders and timed delivery slots are eradicated along with problematic ad-hoc access to materials on-site and obstacles associated with logistics to the point of installation. Installation is much faster with only three connections to be made (inlet, outlet and power).

WE ARE HERE TO HELP

Our design team is here to support your project.

For a full list of configurations and specifications, please fill out the form or send an email to info@projectfire.co.uk

Featured FAQs

What is a Firepod?

Firepods are pre-fabricated units designed for two key areas of a sprinkler system; namely the start of sprinkler zones and sprinkler installations. Apart from the water supply, the majority of the rest of a sprinkler system is just pipe and sprinkler heads but these two key areas contain important additional equipment which takes time to install on-site. The start of a sprinkler installation typically contains an alarm valve, trim including pressure-switch, pressure gauges, monitored isolation valves and more. The start of a sprinkler zone typically contains a Zonecheck (inclusive of flow-switch), monitored isolation valve and drain function. Our Firepods contain all of the approved equipment you will need for installations and zones in a pre-fabricated, pre-tested unit which is manufactured off-site ready for easy delivery and fast installation.

Can Firepods be connected together?

Yes, all our Firepods have a consistent dimension from floor to the centre of pipe meaning they can be easily connected together even when mixing sizes. Our Zonecehck Firepods are designed to fit together for larger number of zones (three or more). When joined together, all equipment is still accessible for testing and maintenance purposes.

What are the advantages of using Firepods?

Our Firepods share many of the advantages of other pre-fabricated units which are constructed off-site including reducing on-site labour, fast installation, increased quality control measures and better co-ordination by planning the exact design ahead. Firepods were designed in 3D CAD to be space efficient whilst retaining the ability to access all equipment for future servicing/maintenance works. Firepods save riser space and plant space by knowing the exact size of the units in advance, rather than agreeing a space for the on-site installers to work within. Firepods can also save money in capital costs by reducing onsite labour and expensive prelims this entails. Delivery is also a problem for most large construction sites with deliveries having to be booked on and then stored on-site; with Firepod, the amount of deliveries is significantly reduced and they can placed in position straight away meaning no storage or security worries. Each and every Firepod is pressure tested and electrically testes before being delivered to site meaning that the reparation works on-site are reduced.

How are Firepods secured in place?

Firepods come with adjustable feet in order to get the units level and firm. Firepods also come with adjustable wall brackets to secure the unit in place with anchor bolts or similar. If required, the Firepod can also be secure to the floor.

Are BIM files available to download?

Yes, Revit families have been created for all types of Firepods. Please contact us to request the files and we will send them over to you.

Zonecheck is simple and sustainable solution for performing sprinkler system flow-switch tests.

Flow-switches installed on a sprinkler system are required to be tested on a quarterly basis, Conventionally during a routine test, water is discharged from the down stream end of the pipe, causing a drop in the pressure. This pressure difference across the flow-switch generates a water flow causing the flow-switch to operate.

Our Zonecheck system is the modern way to carry out this important test quickly, efficiently and inexpensively saving 100% of the water normally discharged to waste. Zonecheck simplifies testing by re-circulating the water within the pipe around the flow-switch, to simulate the flow of one sprinkler head in operation, regardless of where the Zonecheck is installed or located on the system. Zonecheck is simple and easy to use, requiring no specialist skills and this flow-switch test system can be operated at any time. It does not require evacuation of the building and therefore has no effect on normal functioning of the building.

System

Benefits

With Zonecheck testing is easy. A fully code compliant test can be carried out via a simple key-switch.

Zonecheck is 100% water saving. It also indirectly save energy normally used to run large fire pumps to refill the system.

With Zonecheck, as no water is discharged, testing is easy, takes less time and requires no additional manpower.

Remote testing can be executed from a convenient location via the remote key-switch.

Zonecheck’s method of testing is the only way to accurately test to BS EN12845 code standards and only uses LPCB approved components.

Reduced maintenance, Zonecheck recirculates water within the pipe work reducing leaks and no fire pumps are run as a result of testing.

Technical Specifications

Type

BS EN12845 ‘double switch’

Board material

4mm aluminium composite

Board mounting

Unistrut

Pipework

Galvanised steel

Ball valves

Lockable type

Gauges

Glycerine filled with no loss connectors

Non-return valves

Spring loaded type

Test valves

Brass with control orifice

Pressure switches

Bailey & Mackey

Connections (in)

Inlet unions, ½” (15mm) BSP

Connections (out)

1” (25mm)

Board Configurations

Our boards come in a wide range of options (2-way, 3-way & 4-way) or bespoke configurations. Our standard board is a BS EN 12845 compliant ‘double switch’ design up to 14 bar. For installations that require higher pressures we can supply 25 bar initiation boards. We can also provide BS5306 compliant ‘single switch’ boards in various configurations.

CODE COMPLIANCE

Our boards are designed to meet the requirements of BS EN 12845, BS 5306, BS 9990 (wet risers) and LPC sprinkler rules.

We are here to help

Want to know more about how you can simplify your testing routines?

If you want to contact a member of our team, please fill out the form or send an email to info@projectfire.co.uk