Comparison guide and specifications for the new Zonecheck.

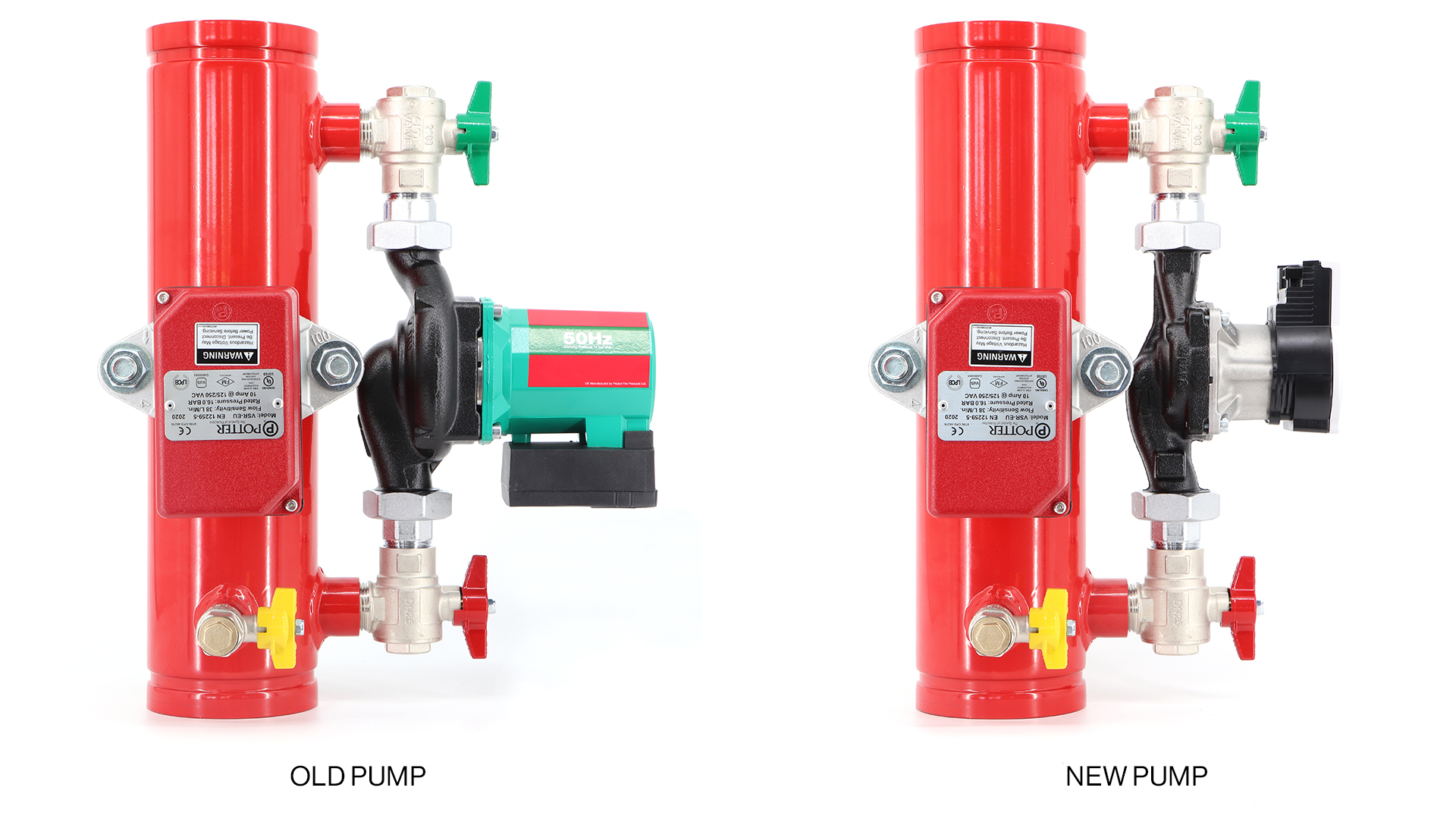

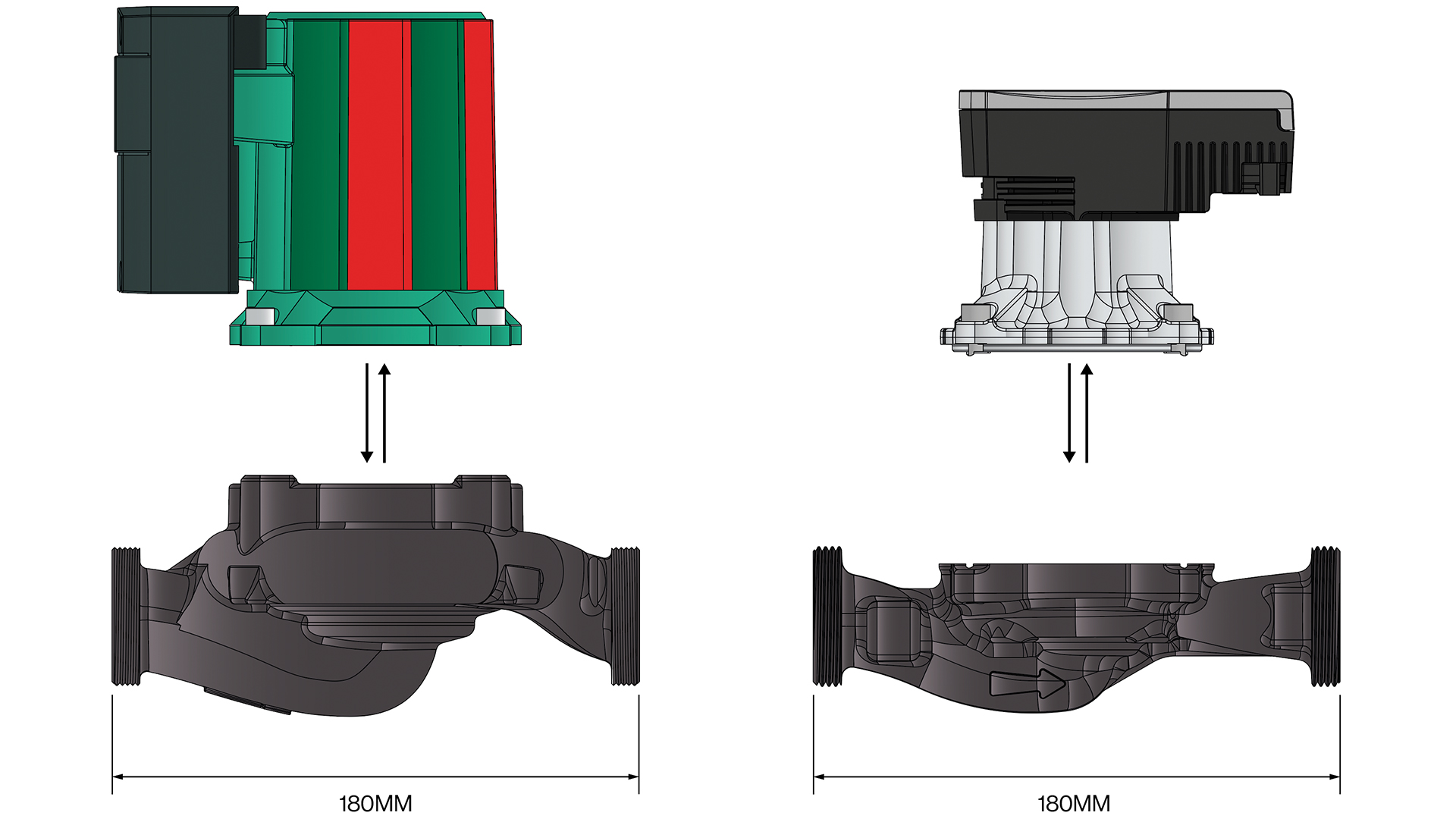

As part of our continuous improvement program we are upgrading the Zonecheck circulation pump. The new pump is a physically smaller pump than the old model, the exact dimensions can be seen below. The pump casting is the same length (inlet to outlet) and the same diameter meaning the new pump is still compatible with older Zonecheck manifolds (this means that pumps can be replaced on older models). The new pump is a more energy efficient pump, lighter, simplifies electrical installation and easier to maintain.

Technical Specifications

The new Zonecheck is a more efficient design and so has a lower power rating than the previous model. The performance of the two pumps is similar and flow rates are controlled via the use orifice plates built into the Zonecheck assembly so functionality remains the same. Below is a side by side comparison of the technical specifications. The max working pressure of Zonecheck remains the same, 12bar (with testing pressure of 18bar). This will be clearly labelled on the Zonecheck unit in a similar way to before. The pump itself is labelled as PN10 by the manufacturer but this pump (within the overall Zonecheck assembly) has gone through all of the rigorous tests from third party approval bodies as the previous model including static pressure testing to over 40bar.

| OLD PUMP | NEW PUMP | ||

|---|---|---|---|

| Type | Wilo | Type | Wilo |

| Operating voltage | 230V 50Hz | Operating voltage | 230V 50/60Hz |

| IMAX | 0.93A | IMAX | 0.82A |

| Max power rating | 195W | Max power rating | 75W |

| IP rating | IP43 | IP rating | IPX4D |

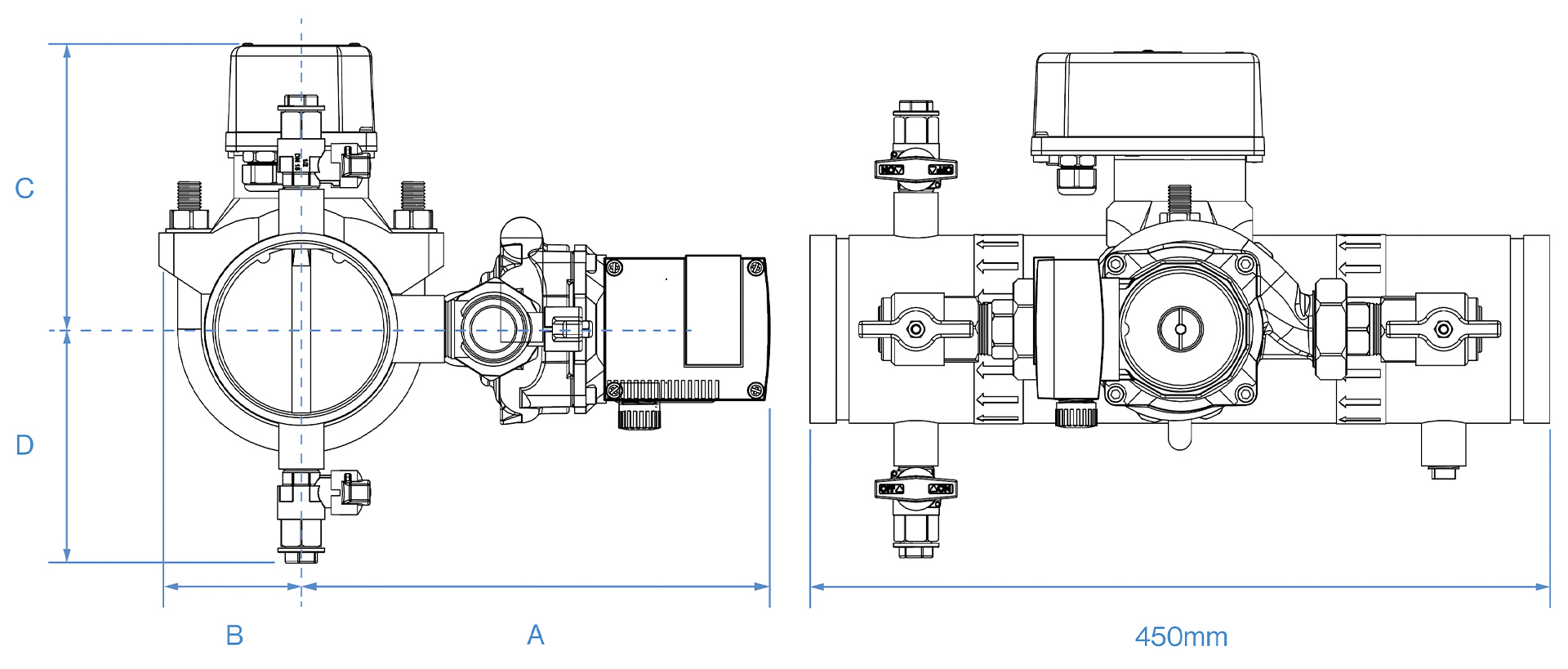

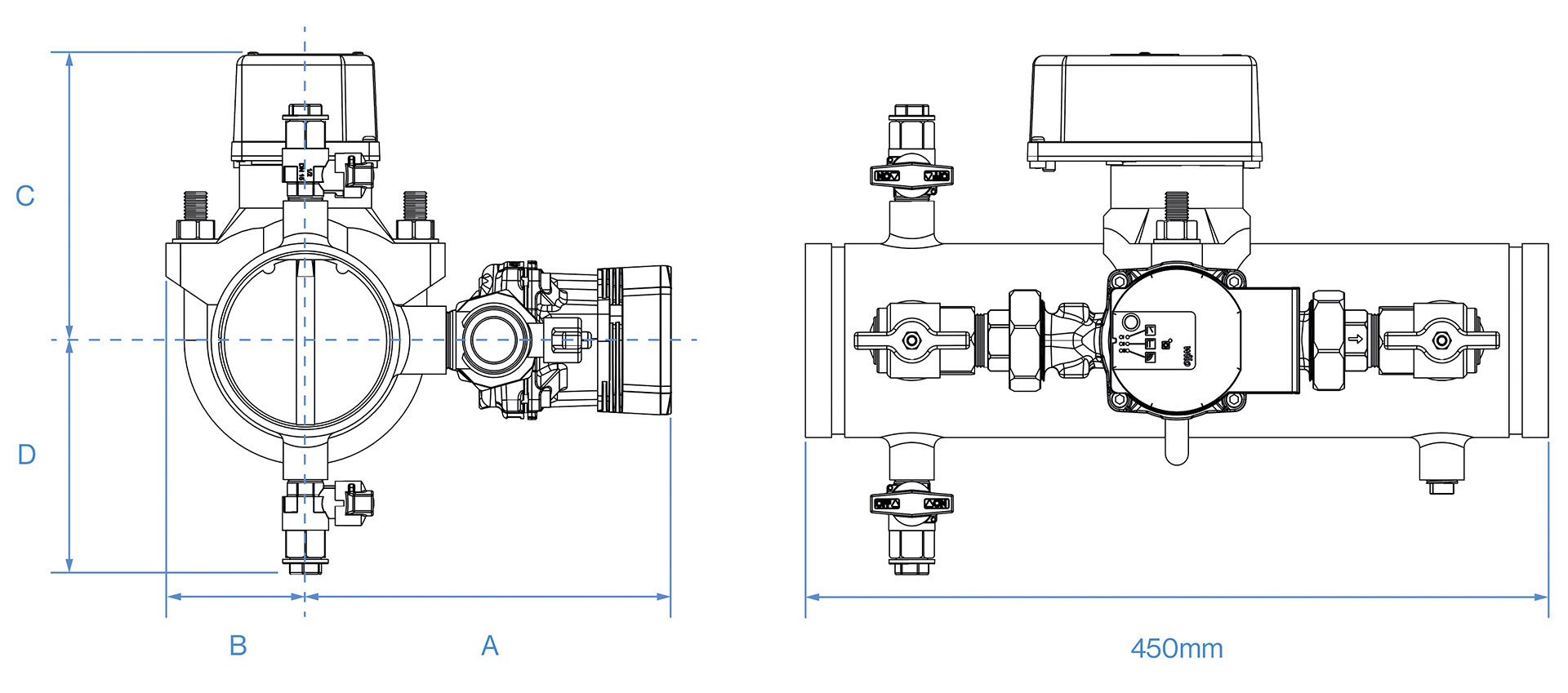

Dimensions

| OLD ZONECHECK | ||||

|---|---|---|---|---|

| ØMM | A | B | C | D |

| 50 (2″) | 256 | 66 | 145 | 116 |

| 65 (2 1/2″) | 264 | 66 | 155 | 124 |

| 80 (3″) | 271 | 85 | 165 | 130 |

| 100 (4″) | 283 | 85 | 170 | 140 |

| 150 (6″) | 309 | 115 | 195 | 170 |

| 200 (8″) | 336 | 150 | 225 | 195 |

| NEW ZONECHECK | ||||

|---|---|---|---|---|

| ØMM | A | B | C | D |

| 50 (2″) | 210 | 66 | 145 | 116 |

| 65 (2 1/2″) | 215 | 66 | 155 | 124 |

| 80 (3″) | 220 | 85 | 165 | 130 |

| 100 (4″) | 225 | 85 | 170 | 140 |

| 150 (6″) | 150 | 115 | 195 | 170 |

| 200 (8″) | 275 | 150 | 225 | 195 |

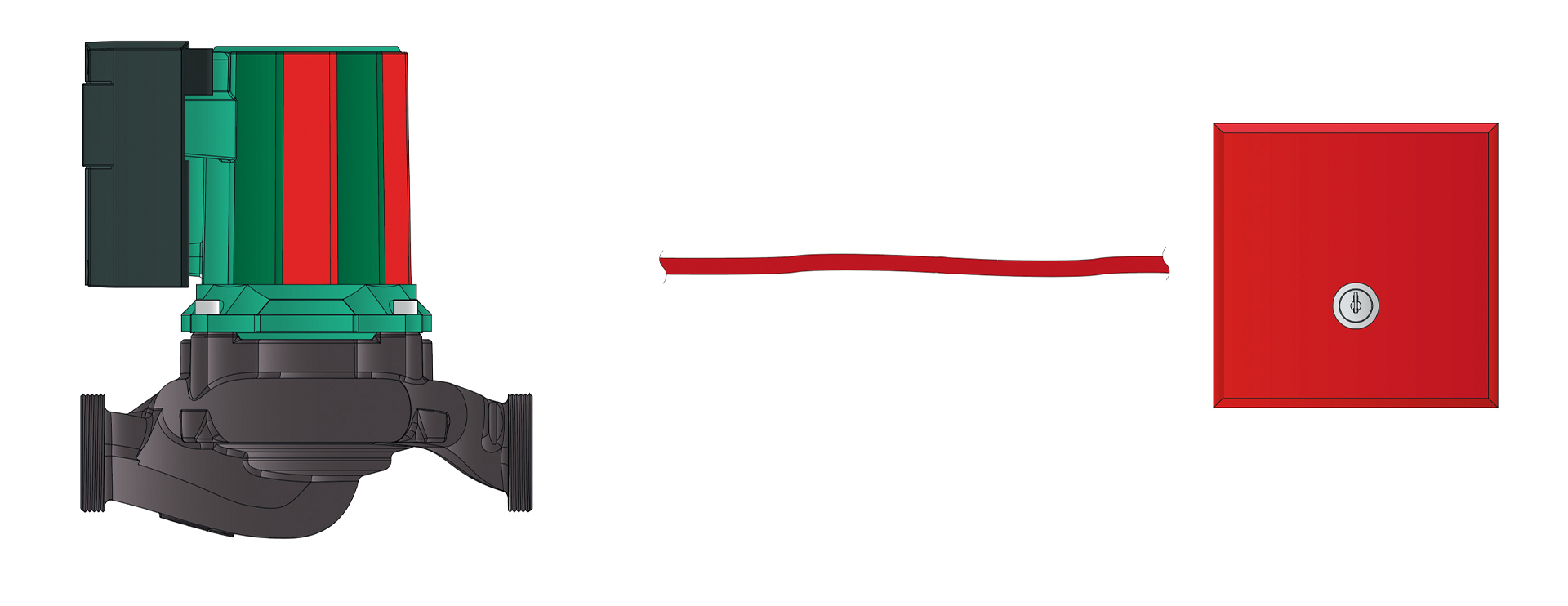

Wiring

The old pump was wired directly into a plastic housing on the side of the pump. The new pump will be supplied with a short fly lead and a male/female connector (see below). The installer will firstly site the key-switch at an appropriate location and then wire from the key-switch to the female side of the connector assembly. This can then be plugged into the connector on the pump fly lead simplifying on-site installation.

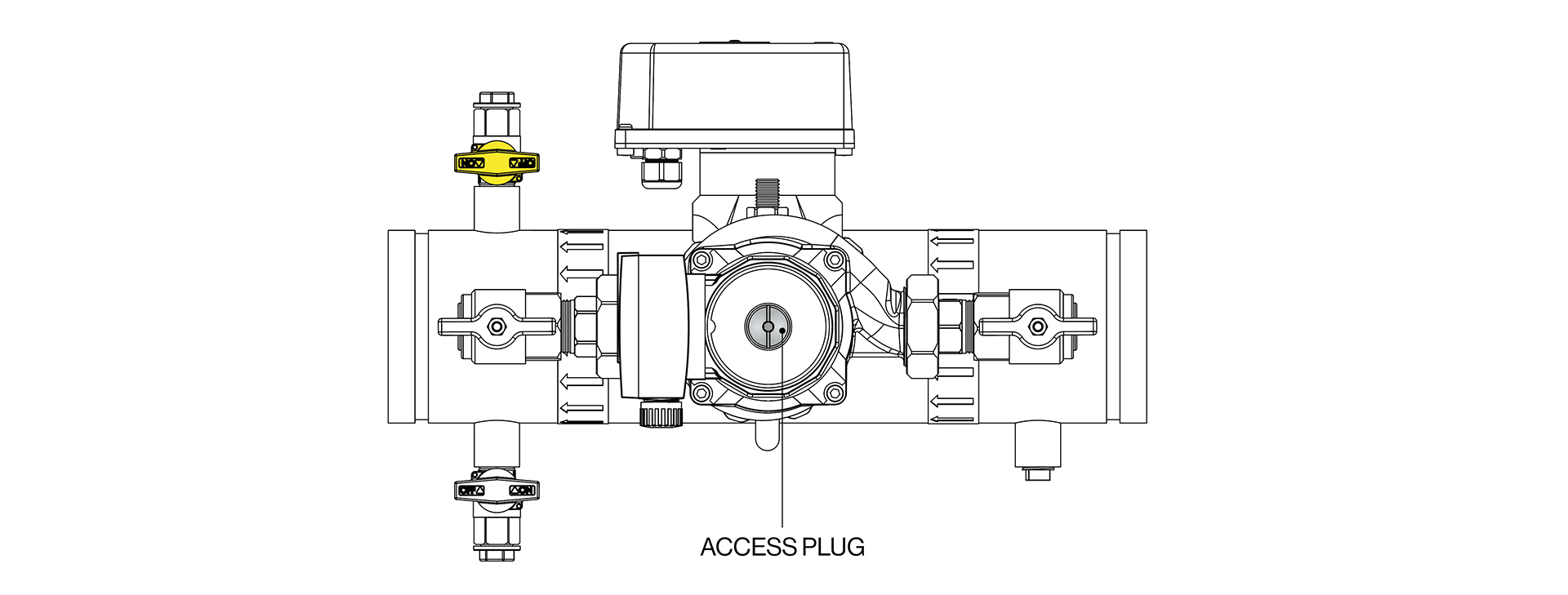

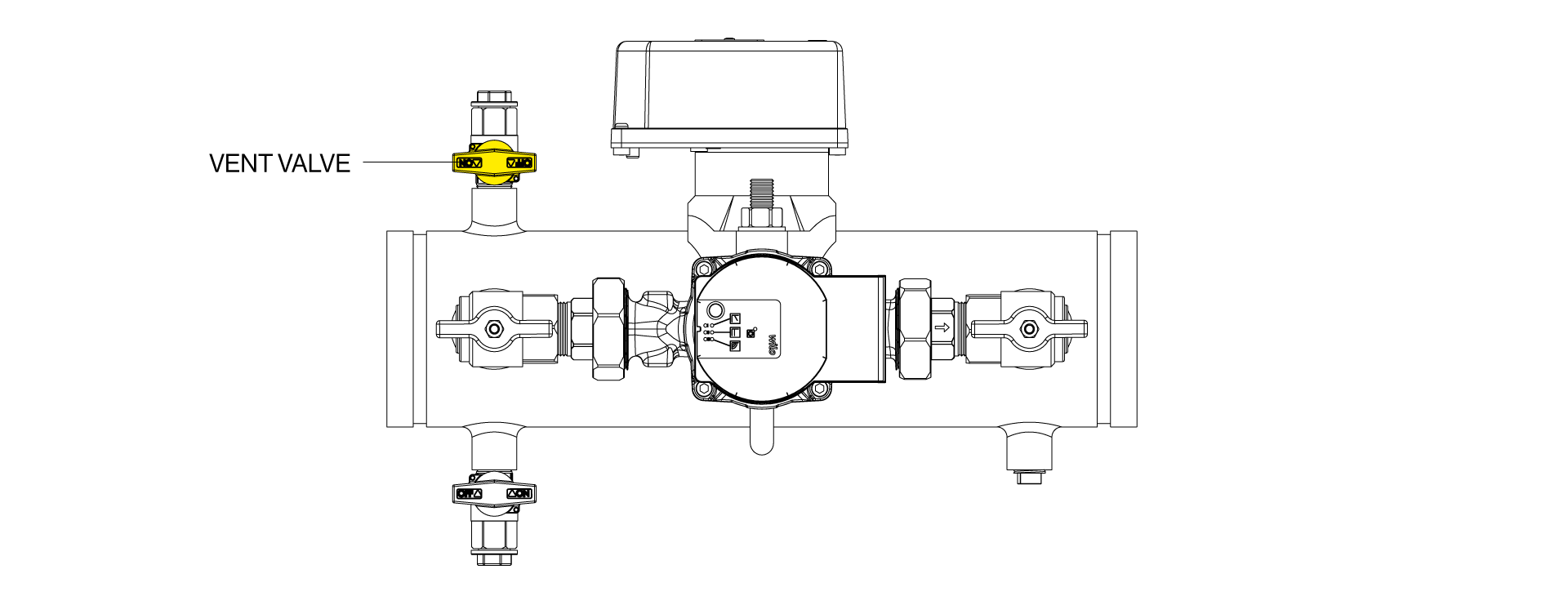

Venting

The new pump is designed to be less sensitive to pockets of air within the water. Zonecheck has always included a vent valve as part of the assembly so the Zonecheck can easily be vented via this means, although the old pump could be vented through a seal at the end of the pump motor assembly.

Venting is an important process to ensure that the pump works efficiently and trips the flow-switch. Venting is only required when the Zonecheck is installed horizontally and once the pipework is vented, it is unlikely to require further venting unless the pipework is drained and the water replaced.

The new pump is self venting and has the ability to push air out of the pump, although if you still continue to experience trapped air causing failed tests you can open the yellow vent value to discharge water to remove any further trapped air. You can view the new venting procedure for the new pump here.

Pump Replacement

The old pump has proven itself to be an extremely reliable pump and has been in service for over 20 years. In rare cases the pump can can cease if manufacturers guidelines aren’t followed, for instance when a Zonecheck is installed and no flow-switch testing has been carried out for a prolonged period of time.

The new pump model should provide a longer life span than the previous pump model (as long as manufacturers guidelines are followed) based on the life-cycle testing performed in-house at Project Fire.

PUMP REPLACEMENT PROCEDURE

For both the old and new pump the replacement procedure is the same. If either of the pumps need to be replaced then there are two main ways to do this:

- Replace the pump motor only (easiest method)

- Replace both the pump motor and casting as an entire pump replacement.

It is important to note that the old and new pump heads are not interchangeable. However, an entire pump (motor and casting) are interchangeable (as the distance between the red and green valves remain the same). Project Fire will hold a stock of the old pumps for maintenance purposes but once these have gone, older Zonechecks that require a replacement pump will have to replace both the motor and casting.

Products Affected

- Zonecheck

- Zonecheck Retro-fit

- Zonecheck Pre-wired

- Zonecheck Addressable

- Zonecheck Econ Aqua (mist)

- Zonecheck Live

- Zonecheck Residential (galvanised)

- Firepod